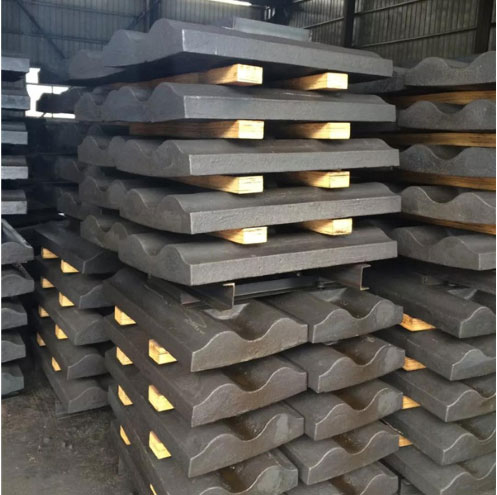

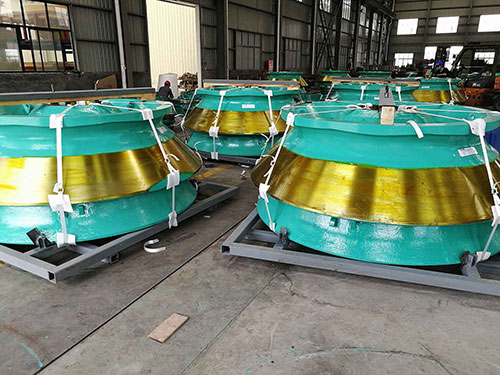

■ Rotary Kiln Support Roller Introduction

Rotary Kiln Support Roller bears all the weight of the rotating body, and the quality of the Support Roller determines whether the entire rotary kiln equipment runs smoothly. Due to its heavy weight and thick section, the casting quality and machining accuracy are required to be high. Usually the materials are cast steel and ductile iron.Our Rotary kiln Support Rollers can OEM for CITIC,Sinoma,NHI,PengFei,Heidelberg, Lafarge and other brands of cement equipment.HENGIN'S Ductile iron Support Rollers instead of steel castings can effectively reduce production costs and shorten production cycles. Ductile iron castings with large cross-sections have excellent comprehensive mechanical properties. QT700-2 ductile iron Support Rollers has high hardness, good wear resistance, good lubricity and shock absorption, which can reduce production costs and improve overall benefits.

■ Ductile iron Support Rollers Metallographic Structure

According to GB9441-2009 "Metallographic Inspection of Ductile Iron", the metallographic structure of the attached cast specimens is checked as follows: spheroidizing grade is not less than 4 grades;

metallographic structure is pearlite, the number of pearlite is more than 90%, the grade is "pearl 95"; dispersed ferrite is "iron 5"; phosphorus eutectic is "phosphorus 0.5" and carbide is "carbide quantity level". Press "carbon 1".

metallographic structure is pearlite, the number of pearlite is more than 90%, the grade is "pearl 95"; dispersed ferrite is "iron 5"; phosphorus eutectic is "phosphorus 0.5" and carbide is "carbide quantity level". Press "carbon 1".

■ Technology Requirements

◆ Material designation: ZG42CrMo,ZG35CrMo,QT400-18,QT500-7,QT700-2A;

◆ Support Roller hardness after Quenching and tempering or normalizing heat treatment δs≥490,HB≥200;

◆ Carry out ultrasonic inspection after rough machining and carry out according to GB/T 7233—2009 standard II or III;

◆ After finishing, magnetic particle inspection is carried out on the machined surface of the parts, according to the regulations of grade GB /T 9444—2007Ⅱ or III;

◆ Thick section and long solidification time are not conducive to ensuring spheroidizing grade.

◆ Support Roller hardness after Quenching and tempering or normalizing heat treatment δs≥490,HB≥200;

◆ Carry out ultrasonic inspection after rough machining and carry out according to GB/T 7233—2009 standard II or III;

◆ After finishing, magnetic particle inspection is carried out on the machined surface of the parts, according to the regulations of grade GB /T 9444—2007Ⅱ or III;

◆ Thick section and long solidification time are not conducive to ensuring spheroidizing grade.