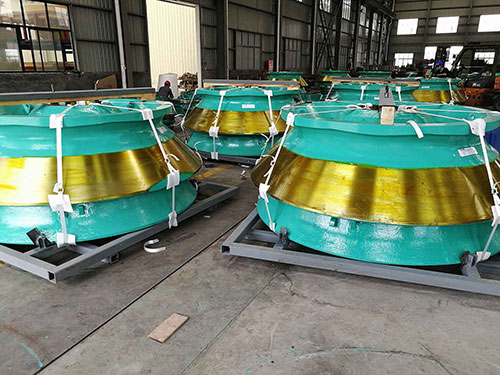

■ The backup roll is an important part of the metal rolling equipment. The working conditions are harsh, and various periodic stresses are applied during work. Therefore, high requirements are placed on the performance of the backup roll.

■ First, we applied the Gleeble-1500 thermal simulation experimental machine to experimentally determine the mechanical and thermodynamic properties of the supporting spoke materials. Using De-Fonn-3D simulation software, the forming processes of different anvil shapes and reductions are simulated and compared, a reasonable forming plan is found, and a reasonable manufacturing process is formulated, which plays an important role.

■ In addition, although smelting technology has made great progress, defects such as segregation, loosening and inclusions of steel ingots are still difficult to avoid completely.The degree of sinking is becoming more and more serious, and it is difficult for traditional forging methods to completely eliminate the defects in large steel ingots. We use 50t electroslag furnace for electroslag remelting to fully purify molten steel and reduce the influence of inclusions and harmful gases and elements as much as possible. Ensure the quality of the internal and microstructure of the large support roller.

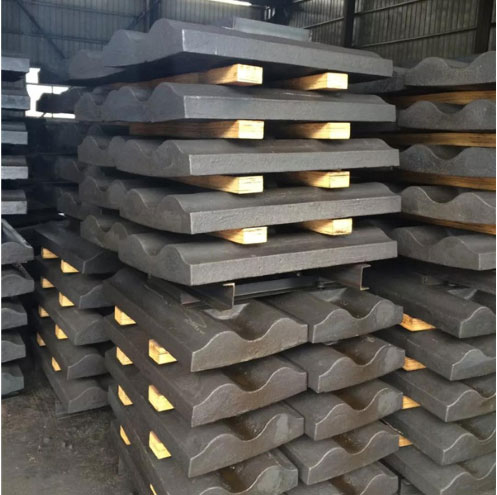

■ Large Backup Roll Material:70Cr3Mo,45Cr4NiMoV.

■ Backup Roll Weight :10-150t.

■ Backup Roll Manufacturing process:

Casting Steel Ingot Model→Casting Steel Ingot→Forging Steel Ingot→Heat Treatment→Machining.

■ Large Backup Roll Manufacturing Equipment:

30t/50t/80t electric arc furnace, 50t electroslag remelting furnace, 8Kt hydraulic press, 18.5Kt hydraulic press, DL series CNC super heavy duty sleeper and other equipment.

■ HENGIN Backup Roll Features:

heavy-duty, high purity of molten steel, relatively small gross net, high comprehensive mechanical performance, short manufacturing cycle.