Home / About Us

Our

Company

Company

Our company is located in Free Trade Zone Luoyang District, Henan Province, China, Henan Province. Luoyang City is China's heavy industry manufacturing base, mining machinery manufacturing, low-speed heavy-duty gear processing, casting and heat treatment center, with heavy equipment state key laboratory, mining machinery engineering designing institute, as well as a variety of scientific research units, physical testing and chemical analysis testing institutions.It has various types of metallurgical equipment, refining equipment, forging equipment, welding equipment, as well as various testing equipment.

In such a strong industrial base environment, our company has a number of professional and technical personnel, management personnel, master advanced technology and industrial expetise, we provide customized design and manufacture of high-quality products and services for our customers in various industries.

In such a strong industrial base environment, our company has a number of professional and technical personnel, management personnel, master advanced technology and industrial expetise, we provide customized design and manufacture of high-quality products and services for our customers in various industries.

Our

Advantages

Advantages

We have been adhering to the concept of professionalism, concentration and precision in product design, process formulation, production, quality control , to create greater value for users.

Our professional technical team can do product design, process design, material design, finite element analysis, quality control, cost accounting, integrated system management, according to the requirements of user to complete the design plan, process plan, formulate quality control ITP plan. Good Connection with workshop, to complete product production and quality control.

Our professional technical team can do product design, process design, material design, finite element analysis, quality control, cost accounting, integrated system management, according to the requirements of user to complete the design plan, process plan, formulate quality control ITP plan. Good Connection with workshop, to complete product production and quality control.

Our

Products

Products

Mining machinery equipment mainly include: Ball mill, AG mill,SAG mill, HPGR, Crusher, etc.

Transportation equipment: Belt, Scraper Conveyor, etc.

Transportation equipment: Belt, Scraper Conveyor, etc.

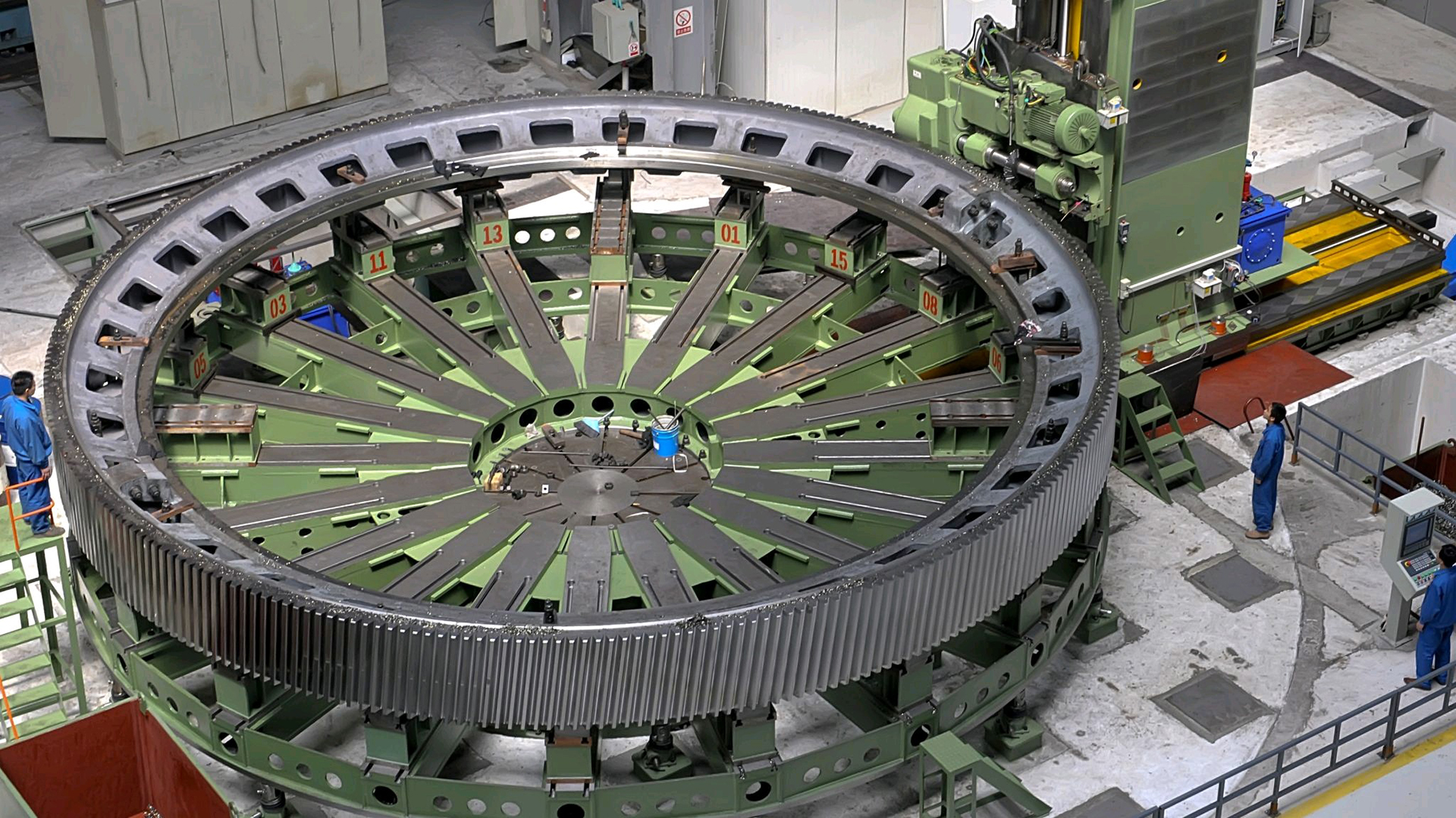

Castings and forgings mainly include: Grinding mill girth gear, Grinding mill head, Babbit&Bronze bearing, Pinnion shaft, Ductile iron castings such as Wind power shaft, Cast steel ball, Forged&Rolled steel ball

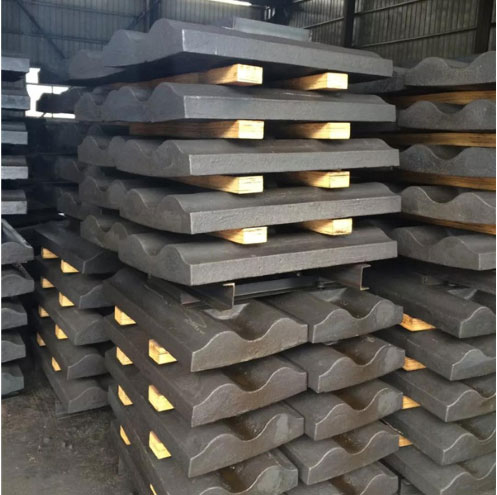

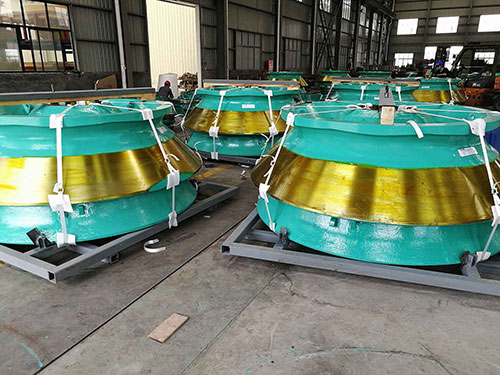

Wear-resistant liners include: Chrome Moly liners(CrMo), High Maganese Liners(Mn), Polymet Liners (Steel and Rubber Composite), Rubber Liners, Magnetic Liners for SAG Mills, AG Mills, Ball Mills, VTM Mills and CSM Mills which are broadly used in gold mine, copper mine, iron mine, molybdenum mine, copper-cobalt mine, nickel mine, lithium mine, etc. We also do engineering and supply of various types liners for gyratory crusher and cone crushers.

Other products and services: Ball pressing machines, Molybdenum crucibles, Riveted weldments, etc. Provide technical consultation, technical services, material testing, and engineering of the above products, customized design and supply according to user requirements.

We can provide spare parts and related consulting services for mining machinery products by Metso, FLSmidth, CITIC and NHI, etc.

Our

Value

Value

Professional design, process, manufacturing, quality management team and rich experience accumulated to provide users with excellent quality products.

Provide all-round creaties product improvement and optimization programs for users to minimize costs and explore value space.

The combination of fine product quality control and efficient production schedule control ensures the product manufacturing cycle to be good and fast.

Provide the whole process of technical exchange, logistics, customs, standards, regulations, culture and other services as well as product installation, consultation, maintenance and other after-sales services.Provide the whole process of technical exchange, logistics, customs, standards, regulations, culture and other services as well as product installation, consultation, maintenance and other after-sales services.

Our Professionals

Guo WG

A mill design expert, 23 years of experience, a senior engineer, presided over the design of the once largest mill Φ10.37×5.19m SAG mill and Φ7.32 ×12.5m ball mill in Dashan Mine of China Jiangtong Group, has rich experience in type selection, design, installation and debugging of mill and on-site problem handling, has worked over a long period of time in the domestic mining machinery leading enterprise and now is the chief designer of our company.

Wang TY

A simulation analysis expert, 10 years of experience, a senior engineer, long-term engaged in mechanical design, manufacturing process, on-site tracking and analysis work. Proficient in all kinds of software, have deep experience in Procast, DEM and other simulation software, form a simulation application database, have deep experience in stress simulation, casting and forging simulation, has worked over a long period of time in the domestic mining machinery leading enterprise and now is the chief simulation simulator of our company.

Liu XD

A foundry expert, 15 years of experience, a senior engineer, long-term engaged in the field of mining machinery casting steel, cast iron process design has rich experience, can formulate casting process plan according to various drawings and user requirements, especially good at relatively large castings process design, such as mill ring, end cap, rolling mill arch products, skilled application of various design software, has worked over a long period of time in the domestic mining machinery leading enterprise and now is the chief foundry technician of our company.

Yin LT

A material, testing and analysis expert, 16 years of experience, a senior engineer, long-term engaged in material research and development, testing work, deep understanding of metal phase transformation, according to the working conditions of parts and components to determine the material scheme, skilled use of various microscopes to analyze metallographic, mechanical testing, formulation of large-scale casting and forging heat treatment process and practical rich experience, has worked over a long period of time in the domestic mining machinery leading enterprise and now is the chief analyst of our company.

Yang SY

A machining specialist, more than 40 years of experience , a senior engineer, have been engaged in the production, technology and management of mining machinery processing for a long time. They have rich practical operation, process technology and workshop management. They can determine machinery processing equipment and formulate process plans according to product quality requirements. They have saved costs and improved production efficiency,has worked over a long period of time in the domestic mining machinery leading enterprise and now is the chief mechanical processing technician of our company company.