Crusher Spare Parts must ensure that it runs at the highest performance. The spare parts are manufactured in accordance with the latest technical specifications and key tolerances, which can ensure that users can more easily replace components accurately.

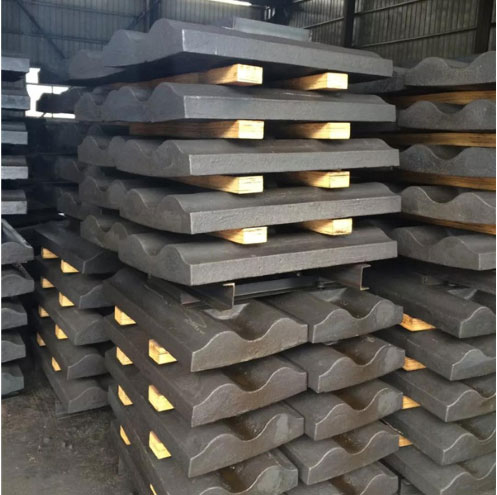

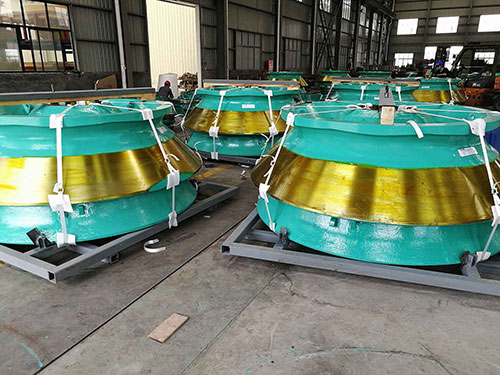

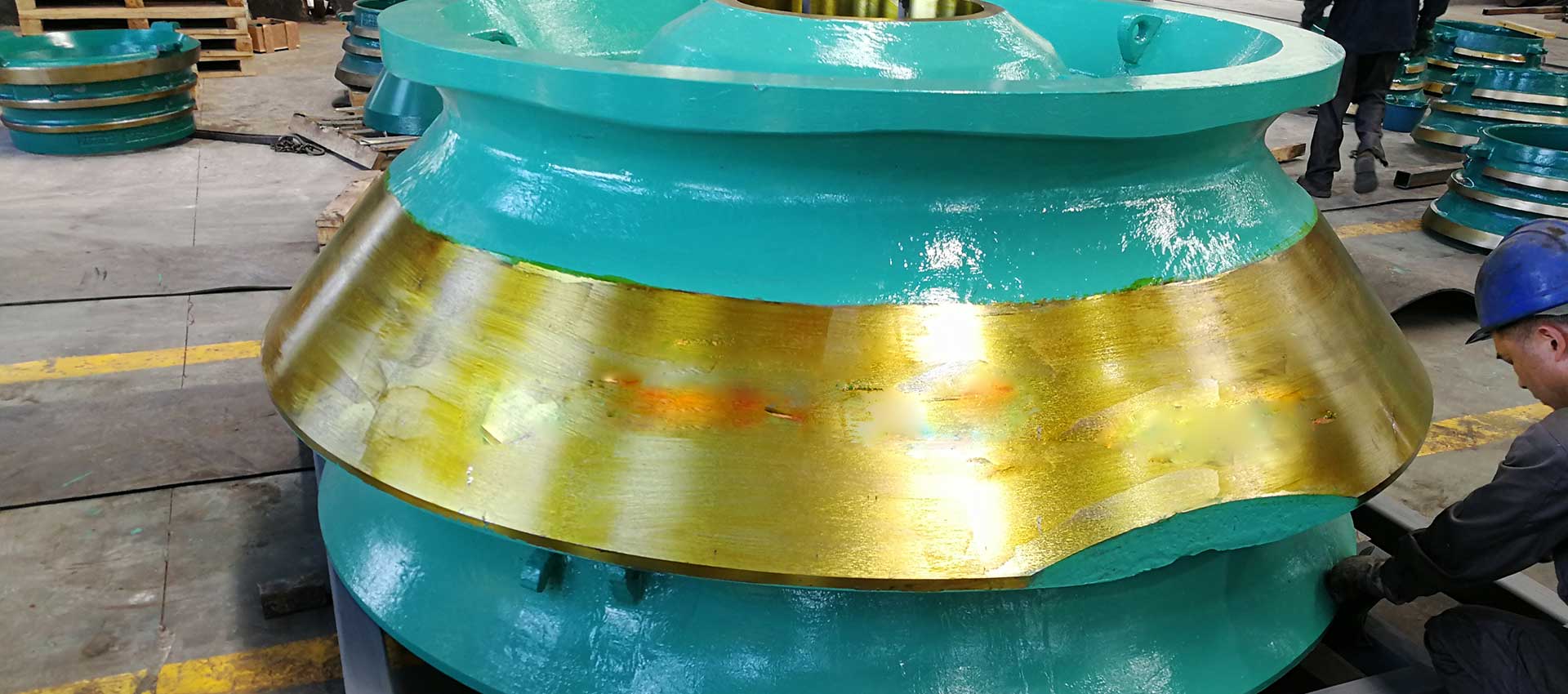

HENGIN'S OEM Crusher Spare Parts products include hydraulic cone crusher, jaw crusher, gyratory crusher main frame, adjusting ring, copper sleeve, bearing, hydraulic parts, electrical parts, assembly, cone crusher fixed cone, movable cone liner, gyratory crusher upper and lower main shaft liner, jaw crusher liner, etc. We can minimize the time delivery. Cone Crusher Liners material is high manganese steel. After water toughening, a single austenite structure with excellent toughness and non-magnetic properties can be obtained. Its characteristic is that under the action of large impact force and contact stress, its surface layer will rapidly harden, the crystal deforms and forms martensite, thereby producing a wear-resistant surface layer, while the inside is still austenite, maintaining excellent impact toughness. Even if the parts are polished very thin, they can withstand large impact loads without breaking. Generally smelting of high-manganese steel is carried out in an electric furnace. One of the indicators for evaluating the smelting quality of high-manganese steel is the number, type and distribution of inclusions in the steel. The coarse, low-melting inclusions distributed at the grain boundaries have an adverse effect on the mechanical properties and wear resistance of the steel. In order to reduce inclusions, the most important link is to ensure that pure molten steel is obtained during smelting.

■ Crusher Liner cemented carbide composite

Our OEM Crusher Liners use high manganese steel or super high manganese steel as the matrix material of large crusher wear parts, composite inlay hard alloys in their working parts, so that the wear surface of the bimetal composite wear parts has excellent wear resistance, and the non-wear surface has excellent Its plasticity and impact toughness reduce the wear of the base high manganese steel and greatly increase the service life of the cone crushing mortar wall.In order to improve the performance of the broken wall rolling mortar wall, alloying, microalloying, carbon manganese content adjustment and precipitation strengthening treatment, etc.

■ OEM Crusher Spare Parts Models

| ◆ Cone Crusher | ◆ Symons Nordberg® Cone Crusher |

◆ Shanghai SBM Cone Crusher |

◆ Shanbao Cone Crusher |

◆ Telsmith Cone Crusher |

◆ Minyu Cone Crusher |

|

|

|

✔CH® Series |

|

✔HPC Series |

✔PY Series |

✔Gyrasphere® |

✔MSP® Series |

■ Cone Crusher Liners Material And Mechanical Properties

|

|

◆ Crusher Liner Material ◆ Crusher Liners Casting Method |

|