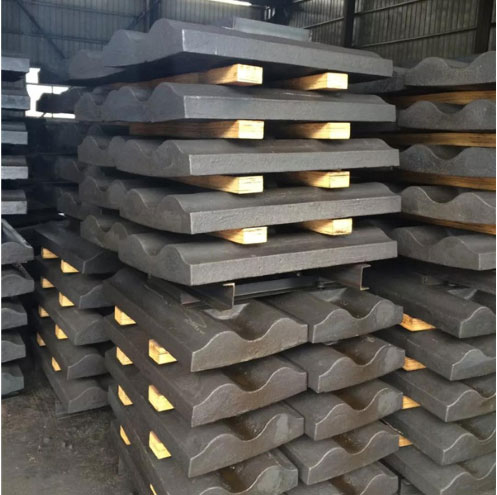

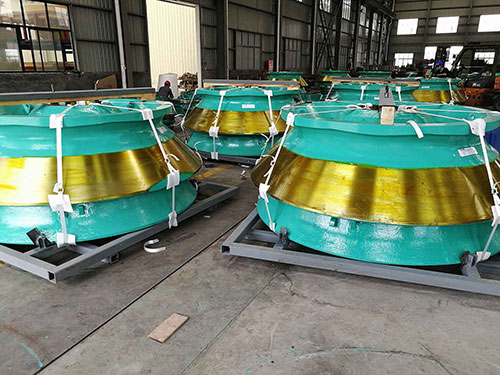

■ Description of Grinding Mill Head

The journal area of the Grinding Mill Head is supported on the main bearing by high pressure oil film during the working process of the mill, that is, the cylinder, material and medium are supported by the Grinding Mill Head; the big flange of the Grinding Mill Head is connected with the cylinder flange and the big gear flange by bolts, and the gear group drives the cylinder to rotate through the Grinding Mill Head, so the Grinding Mill Head of the mill is subject to alternating stress. It is an important force component in the operation of mine mill. With the development of large mills, the requirement for Grinding Mill Heads is getting higher and higher. There are no shrinkage, shrinkage and coarse grain defects in the Grinding Mill Heads, and there are no linear defects such as cracks and non-linear defects such as air holes and sand holes on the surface. Therefore, how to design the casting process reasonably and ensure the casting quality of the Grinding Mill Head has become the key.According to the stress condition of the Grinding Mill Head, the material of the Grinding Mill Head is mainly low carbon cast steel, nodular cast iron, rivet welded parts, high strength gray cast iron and so on. Due to the low manufacturing cost of ductile iron and high strength gray iron castings, the proportion of cast iron Grinding Mill Heads produced in developed countries is relatively large. However, due to the influence of energy, labor price and environment, cast iron Grinding Mill Heads are restricted by many factors such as production conditions, technical level, casting quality and welding performance in China. At present, the large Grinding Mill Head (especially the Grinding Mill Head of mining mill with large force) is mainly made of low carbon cast steel.

■ Material and performance of Grinding Mill Head

Chemical composition of ASTM A216 WCA w B /% Table 1|

C |

Si |

Mn |

S |

P |

Ni |

Cr |

Mo |

Cu |

V |

Fe |

| ≤0.24 | 0.30~0.45 | ≤0.9 | ≤0.025 | ≤0.025 | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.20 | ≤0.03 | rest |

|

Yield Strength/MPa |

Tensile Strength/MPa |

Elongation/% |

Section Shrinkage/% |

Hardness /H B |

| ≥241 | 448~586 | ≥24 | ≥35 | ≥ 130 |