■ Mechanical Properties And Metallographic Structure Of Casting Grinding Ball

Product Brand |

Specifications (mm) |

Hardness (HRC) |

Shock Absorption Energy (J) |

Metallography |

|

Cr5 |

Φ10~130 |

≥50 |

≥3.5 |

M+C |

|

Cr10 |

≥58 |

≥3.5 |

M+C |

|

|

Cr17 |

≥58 |

≥3.5 |

M+C |

|

|

Cr20 |

≥58 |

≥3.5 |

M+C |

|

|

Cr26 |

≥58 |

≥3.5 |

M+C |

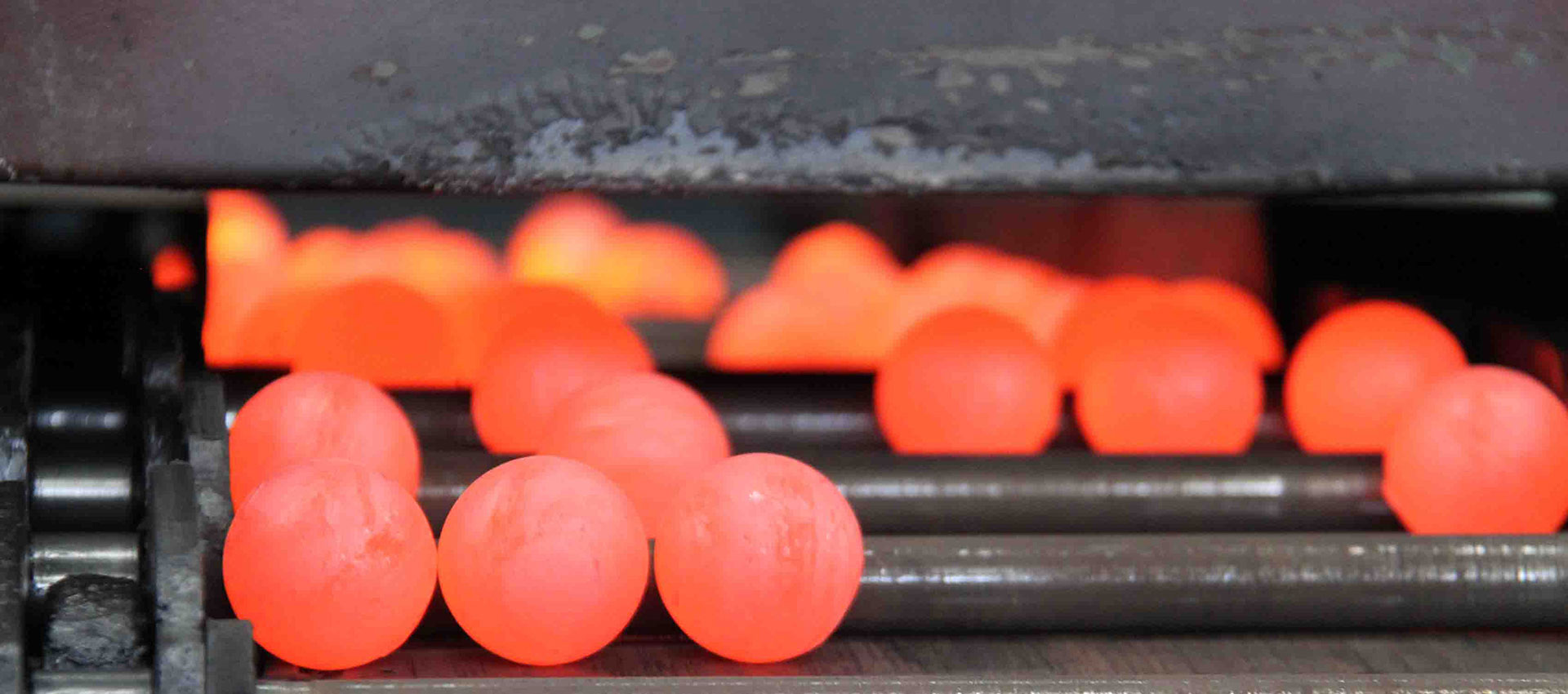

■ Chemical Constituents Of Forged Grinding Ball

Material |

Chemical Constituents ( wt% )

|

|

|||||||

C |

Si |

Mn |

P |

S |

Cr |

V |

Ti |

Cu |

|

B2 |

0.75-1.00 |

0.70-1.20 |

0.80-1.00 |

≤0.030 |

≤0.035 |

0.20-0.50 |

≤0.1 |

≤0.1 |

≤0.1 |

B3 |

0.45-0.70 |

0.30-1.20 |

0.40-1.00 |

≤0.030 |

≤0.035 |

0.20-0.50 |

-- |

-- |

|

B4 |

0.075-1.05 |

0.12-0.32 |

1.05-1.15 |

≤0.025 |

≤0.025 |

0.5-0.6 |

- |

- |

|

■ Technical Requirements Of Forged Grinding Ball

Code Name |

Fatigue Life of Falling Ball Impact |

Rockwell Hardness |

Impact |

|

Surface Hardness (HRC) |

Core Hardness(HRC) |

Toughness Ak(J) |

||

|

H40 |

≥8000 times |

61-63 |

≥60 |

≧12 |

|

H50 |

≥8000 times |

61-63 |

≥60 |

≧12 |

|

H60 |

≥10000 times |

60-63 |

≥60 |

≧12 |

|

H65 |

≥13000 times |

60-63 |

≥59 |

≧12 |

|

H70 |

≥13000 times |

60-63 |

≥59 |

≧12 |

|

H75 |

≥13000 times |

60-63 |

≥59 |

≧12 |

|

H80 |

≥20000 times |

60-63 |

≥59 |

≧12 |

|

H85 |

≥20000 times |

60-62 |

≥59 |

≧12 |

|

H90 |

≥20000 times |

60-62 |

≥59 |

≧12 |

|

H95 |

≥20000 times |

60-63 |

≥59 |

≧12 |

|

H100 |

≥20000 times |

60-63 |

≥58 |

≧12 |

|

H120 |

≥20000 times |

59-62 |

≥58 |

≧12 |