The accuracy of carburized gears should be up to AGMA2101-D04, AGMA6114 and AGMA2015 (A5), quenched and tempered gears should be up to AGMA2101-D04, AGMA6114 and AGMA2015 (A7). Metal inclusions (purity) shall be inspected in accordance with ASTM E45 and meet the requirements of AGMA 6114 Standard.

■ Pinion Shafts Materials and Mechanical Properties

Mechanical Properties |

Material Brand |

||

17CrNiMo6 |

20CrNi2MoA |

30Cr2Ni2Mo |

|

|

Minimum Tensile Strength (Sample) |

1080MPa |

1080MPa |

1000MPa |

|

Minimum yield strength (specimen) |

785MPa |

785MPa |

800MPa |

|

Minimum Elongation |

7% |

8% |

10% |

|

Minimum Section Shrinkage |

40% |

35% |

45% |

|

Shock Value |

Aku≥31J |

Aku≥47J |

Aku≥40J |

|

Hardness (Surface) |

HRC57-62 |

HRC57-62 |

HB300-340 |

|

Hardness (Core) |

≥25HRC |

≥25HRC |

≥25HRC |

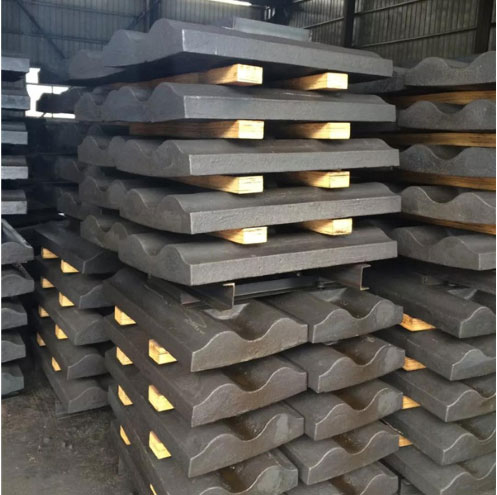

■ Pinion Shaft Manufacturing Process

According to different materials and different requirements, it can be divided into two processes:◆ Casting Ingot →Forging →NDT→Semi-finishing →Carburizing + Tempering →NDT → Grinding Finishing →Dimension Detection.

◆ Casting Ingot→ Forging →NDT→ Semi-finishing →Tempering→ NDT→ Finishing→ Dimension Detection .

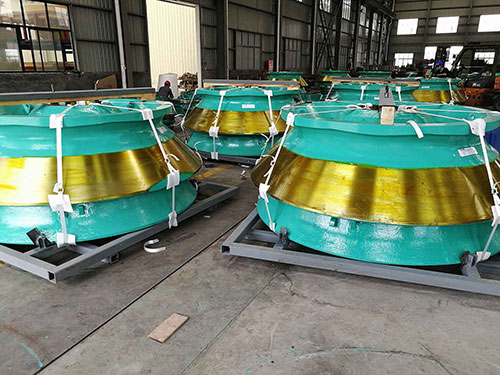

■ Pinion Shafts Detection

After the final processing of teeth, 100% of the contact area and root area of the finishing teeth should be in accordance with AGMA6114 and ASTM.Standard for visual inspection and magnetic particle inspection. Contact area includes tooth surface and other tooth colors. Root area consists of bottom alveolar and transition corner. Shaft part In addition to the keyway, magnetic particle inspection is also carried out in the district.