SAG mill power 18000kw, double motor drive, gear edge drive, the design processing capacity of 25000 tons / day; The mill started operation in June, 2018, with complete set of equipment Φ 7.9×13.6m overflow ball mill. |

The whole set of liner was installed and operated on December 11, 2020, and was removed and replaced on May 10, 2021 due to maintenance in the user's workshop. The total operation time is 148 days, 24% longer than that of the previous set of liner, and the total ore handling capacity is 4.05 million tons. The user is satisfied with the effect of liner board. Because the liners are removed and replaced in advance, it can be used for more than 30 days according to the residual thickness and wear rate of the liner at the discharge end which is the most severely worn.The original design dimension of discharge grid liner thickness is 108mm, and 58mm is left when it is removed. The appearance of SAG mill grate liner of our company is intact, with little wear and tear, no fragmentation, and almost no deformation of grate seam. |

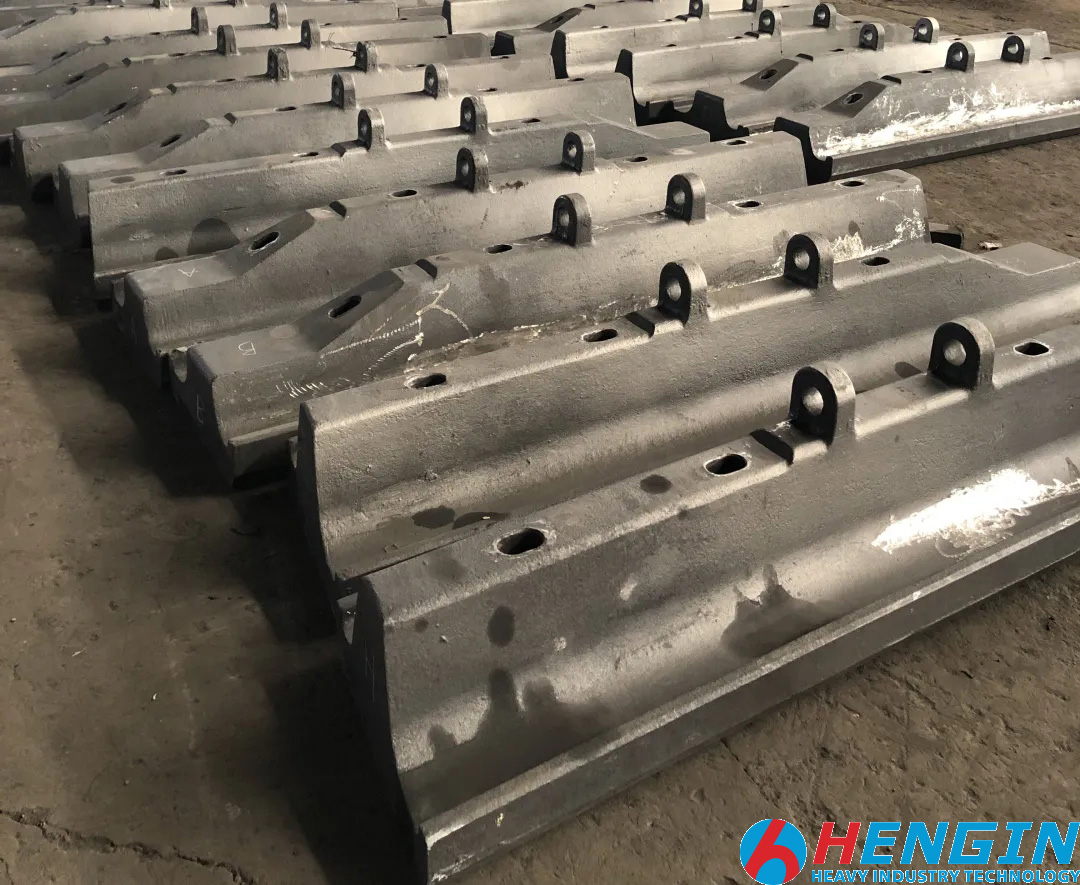

The height of lifting strip of discharge shell liner is 340mm, the thinnest residual thickness is 142mm, and the base plate is 90mm, so the replaced liner can still be used for a certain period of time. |

As the structural design of the discharge shell liner has a slight impact on the handling capacity, the design of the discharge shell liner we supply this time has been adjusted. Instead of using the high-low alternate structure, the original design is still applied, which only optimizes the parameters of the height and angle of the lifting bar. The liner material is still CrMo. The chemical composition of the liner is refined by alloying, and the austenite temperature of heat treatment is controlled more accurately. This set of liners will perform better than the previous one. |