The ball mill shell liners of this batch of Φ 3.6 × 6m are supplied by hengin to Shandong customer copper slag mine project. The original customer used Cr-Mo shell liners with poor effect, so we are entrusted to redesign the material and manufacturing process of the liners to achieve 180 day service effect. However, in order to ensure the qualified discharge particle size, the waveform of the shell liners must be consistent with the original structure. For this reason, we carry out systematic analysis and redesign materials and processes.

one point one The process flow is: crusher + one-stage ball mill + two-stage ball mill to crush slag; the general copper slag grinding process flow is: SAG mill + ball mill can crush to the ideal particle size range, and the iron content of copper slag is more than 70%. After water quenching, the copper slag has the property of steel, and the hardness is very high, which can reach f =12-18 or above It is a great challenge for the shell liner to crush and grind with a Φ 3.6 × 6m ball mill.

1.2 the feeding degree of the first stage ball mill is about F80 = 20-30mm, the filling ball has three gradations of Φ 120mm, Φ 80mm and Φ 60mm, the ball filling rate is 35%, the feed particle size is larger, compared with the ball mill of the same specification, the ball diameter of the filling ball is larger, and the service condition of the liner is worse.

2.1 incorrect material selection direction

The ball mill liner are made of Cr-Mo material. Under the working conditions of copper mine and large diameter ball, the microstructure of Cr-Mo liner is pearlite + massive carbide, and the Hardness is HB320-400, so it is difficult to achieve good wear resistance.

2.2 the wear of different parts of the mill is inconsistent

From the long direction of the mill shell, there is inconsistent wear of the feed, middle section and discharge. The feed end is more seriously worn than other parts due to the direct impact of steel ball and material feeding. There is no difference in the structure, material and process of mill liner, which leads to inconsistent service life of different parts of the mill shell and premature failure of feed end.

2.3 the average service life of the whole ball mill shell liner is 90 days, which is far from the ideal expected 180 days.

In order to meet the requirement of wear resistance of Φ 3.6 mm carbide liner and Φ 3.6 mm martensite liner, it is necessary to improve the wear resistance of the liner State.

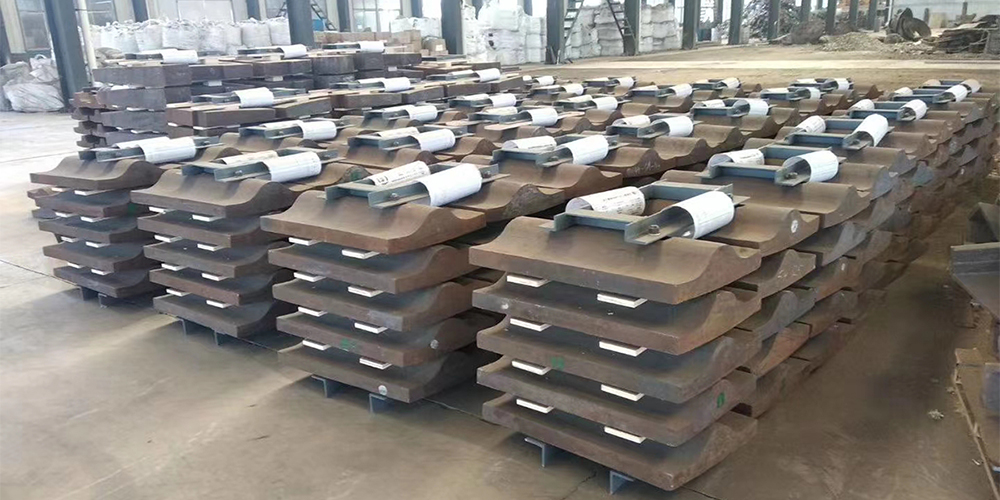

We choose Cr16Mo2 material for the shell liner of the feeding part and Cr12Mo2 material for the shell liner of the ball mill discharge. We design reasonable casting and heat treatment process to eliminate defects, make the morphology and distribution of microstructure and carbide uniform, refine the particle size, and further enhance the wear resistance of the matrix structure. This batch of 354 high Cr Φ 3.6 × 6m ball mill shell liners, 58.9 tons, were sent to Shandong user site on March 15, and have been installed and used recently.