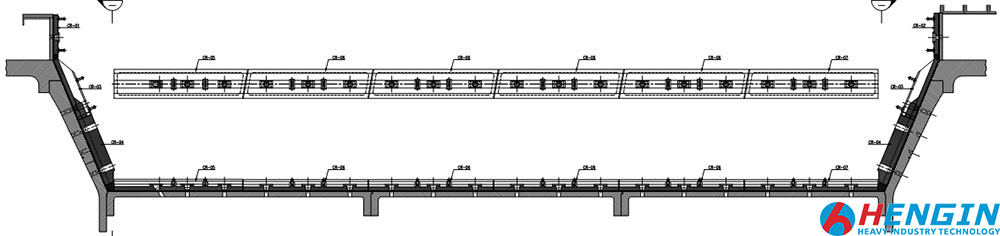

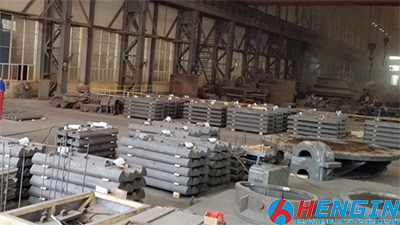

The Φ 7.6 × 12.1m ball mill liner provided by HENGIN for Australian customers was manufactured on February 20, 2021 and loaded and shipped to Shanghai port. A total of 12 trucks of 13m model were transported, and the scene was spectacular.

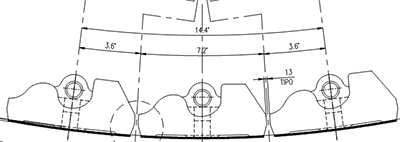

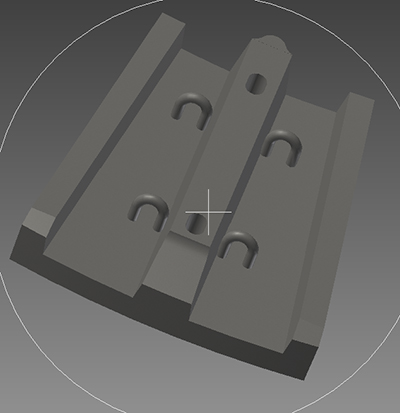

The mine is a porphyry copper mine. The technological process is SABC. The Proctor hardness of minerals is f = 5-8, and the feed particle size of ball mill is F80 = 15mm. Because the minerals are hard and the feed particle size is large, the design of the ball mill shell liners are the combination of waveform and T-shape, so the design structure of the liner enhances the crushing and grinding effect of minerals.

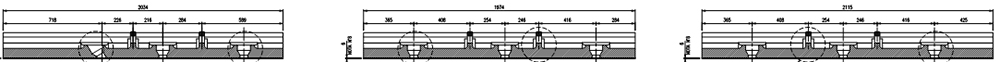

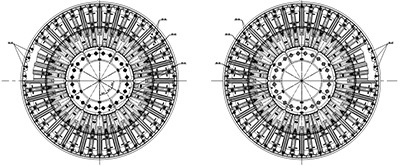

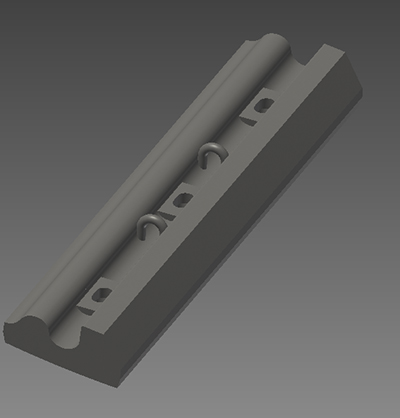

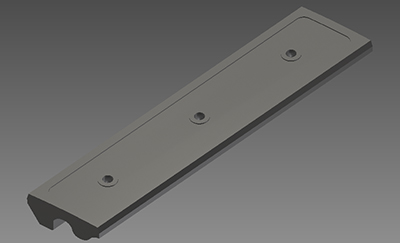

There are three kinds of feeding and discharge liners, a total of 84 pieces, with the weight of 580kg / 595kg for inner ring and 940kg / 930kg for outer ring respectively

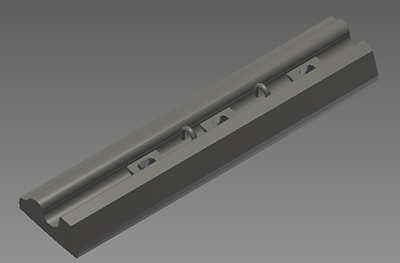

The shell liner is divided into 6 sections in axial direction, 50 pieces / circle in circumference, three kinds of shell liner structure, 300 pieces in total, 100 pieces of 980kg shell liner and 200 pieces of 980kg shell liner. The material of feeding and discharge liner is 85CrMo with heat treatment hardness of HB340-370; the material of shell liner is Cr16Mo2Ni with heat treatment hardness greater than HRC50.

The wave radius r = 76mm, the maximum ball diameter of filling steel ball d = 125mm, the main function of the wave part of liner is to grind minerals; the height of T-shaped part 184mm has a lifting effect on steel ball, which has a good crushing effect on minerals; in addition, the thickness of base plate 76mm is relatively safe and not easy to break, which has a good protection effect on cylinder

20% UT and MT tests were carried out for feeding and discharge materials and shell liner, and the MT test standard was ASTME1253. The test results are good, and no internal casting defects and surface cracks are found.

100% feeding and discharge liners body hardness: HB340-375.

100% ball mill shell liners: HRC50-55.

Impact energy test of liner sample: 85CrMo AK ≥ 25J; Cr16Mo2Ni AK ≥ 8J.

The surface quality of ball mill liner reaches ASTM. A802 after shot blasting.

Hengin has always been a professional technology and means, cost-effective products, responsible working attitude, for the global mining field of user service and create greater value.

|

|

|

|

|

|

|

|

|

|