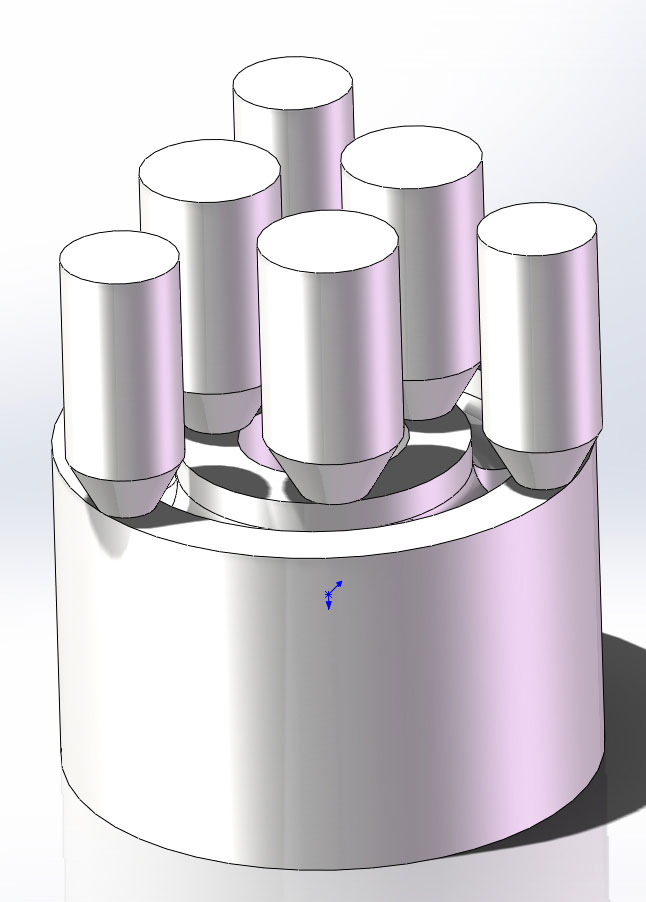

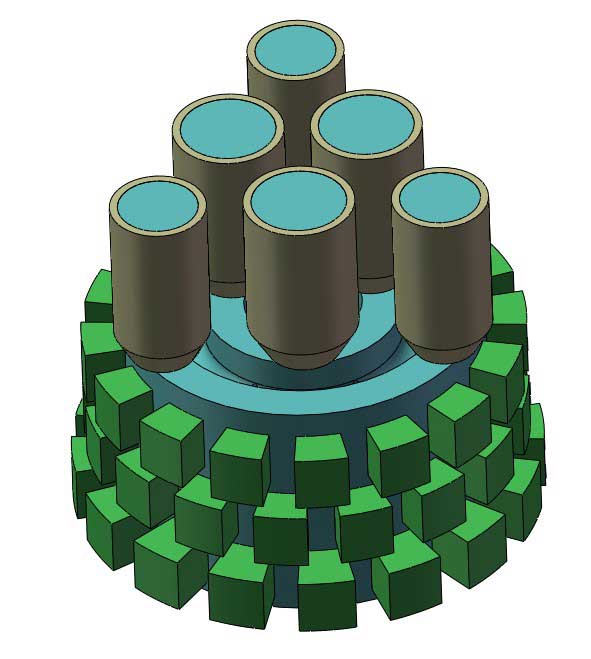

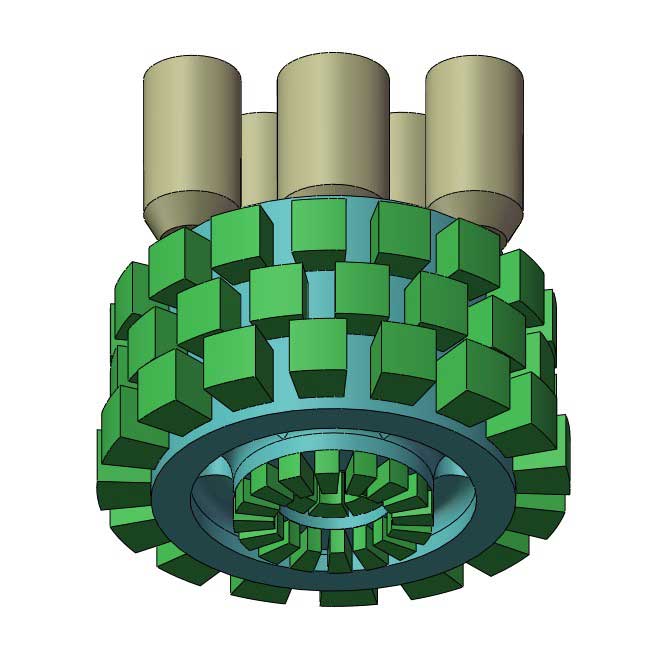

the maximum outer diameter is 1300 mm, the height is 760 mm, the maximum wall thickness is 415 mm, the gross weight is 7.5 T, and the material grade is QT700-2.

the casting quality is accepted according to GB/T1348-2009, and the spheroidization grade of the casting is up to grade 3 according to GB/T 9441-2009;

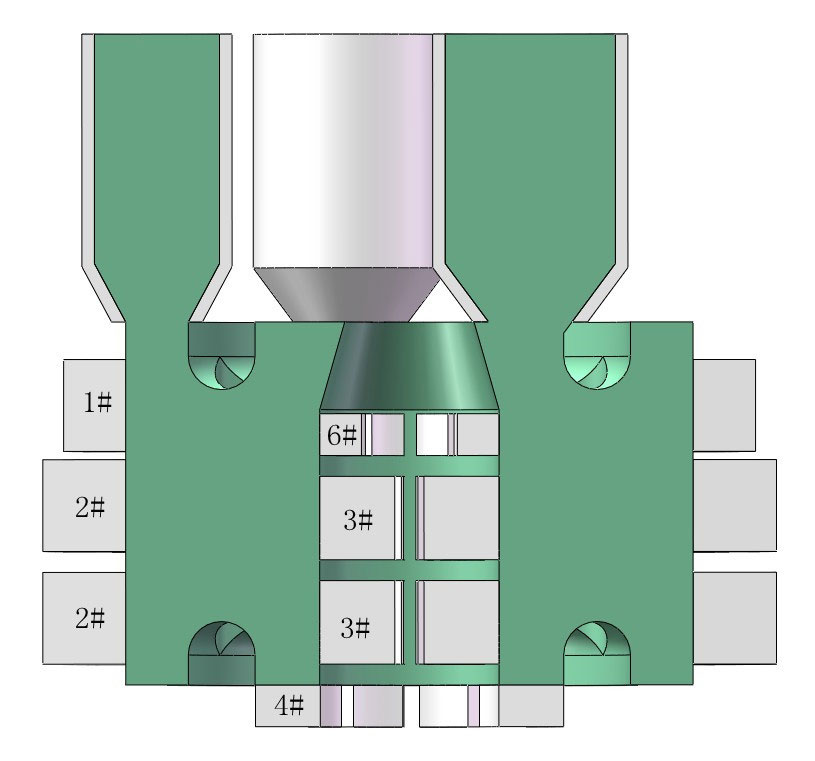

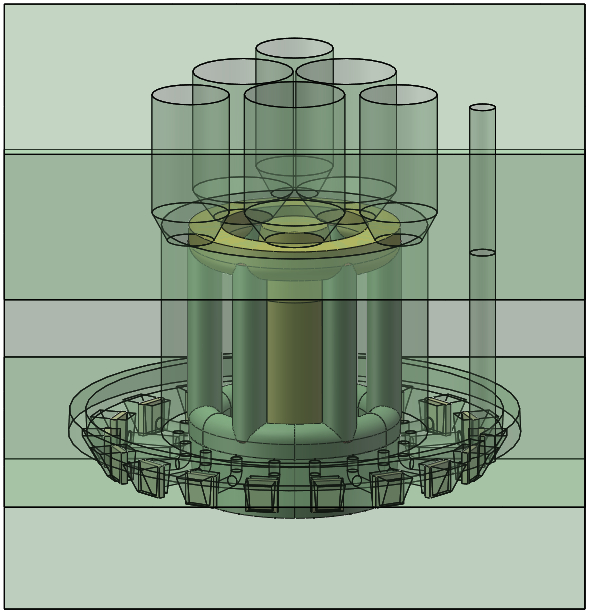

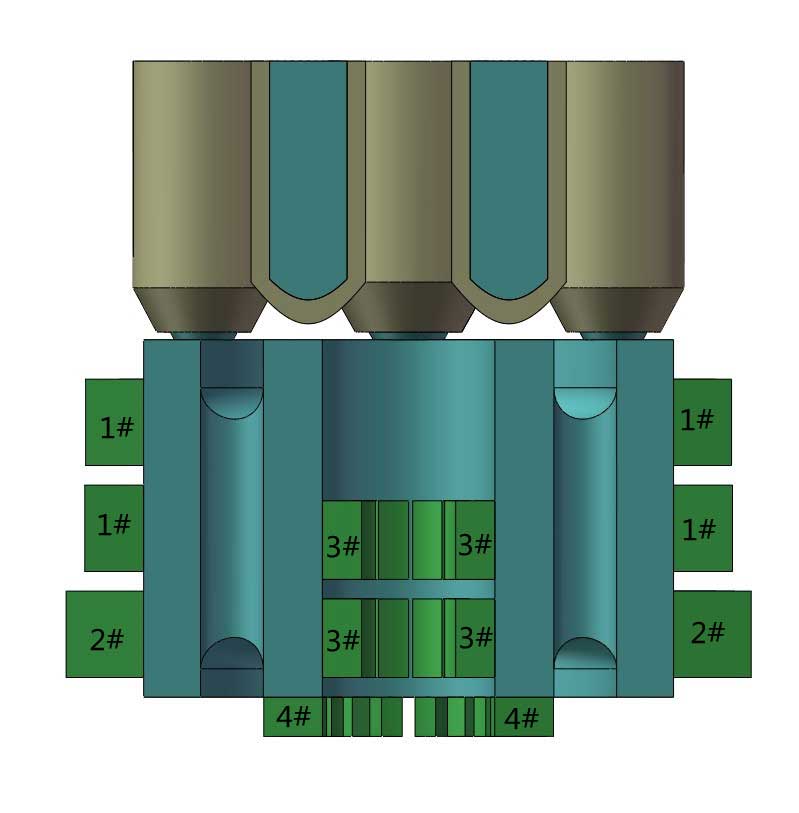

Casting process design is very important. To obtain high quality supporting wheel, the first step is to ensure the complete stamping die, then to ensure that there are no surface and internal casting defects, and to achieve no micro casting defects, compact structure and good performance.

|

|

|

|

|

|

The results show that the cross-section of supporting roller is thick, the solidification time is long, the graphite morphology in the center of wall thickness and hot spot is easy to deteriorate, and the defects of shrinkage cavity and porosity are easy to occur. Manufacturing is very difficult. In order to produce qualified castings, ProCAST simulation software was used to simulate the solidification process and temperature field of nodular cast iron supporting roller, predict the possible defects and take corresponding improvement measures.

|

|

|

|

|

|

The casting process of nodular cast iron roller includes resin sand mold making, smelting, pouring and nodularizing treatment. Each step must be strictly controlled according to the process parameters, especially the nodularizing treatment must be strictly controlled. Only time and temperature can guarantee the shape and quantity of nodular cast iron.

|

|

|

|

After careful process design, accurate process parameter control and rich production organization experience, the shape of the supporting roller casting is complete, there is no casting defects, and rough machining and NDT are needed to detect the internal quality.

|

|

|

|

|

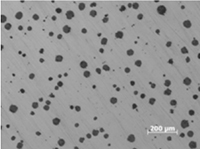

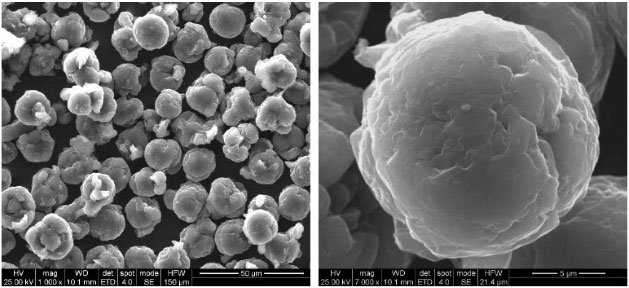

Metallography is based on the test results of cast samples attached to the body of spport roller.

|

|

|

|

| Distribution of graphite spheres in low power optical microscope |

Normalize P-base + G-ball | Annealed F + G spheres | As cast (P + F) base + G ball ox eye shape |

Three dimensional morphology of spheroidal graphite

Through the correct process design and strict production control of the roller products.The results show that the hardness, yield strength and elongation are up to the standard; the spheroidization rate is 85%, and the shape distribution of graphite spheres reaches grade 3; the P content is 90%, and the amount of phosphorus eutectic is 0.5,After machining, the finished product quality of supporting roller is excellent, which has accumulated important process parameters for Sinopec to replace supporting roller of cast steel rotary kiln in batches.