The batch of oval slag pots are products designed and manufactured by us for Middle East customers. Because the customers have no production drawings, they only provide the outline of slag pots and the size of slag pot trucks. We have carried out overall digital structural design and process design for slag pots according to the data and user requirements, so as to realize accurate installation of the size, reasonable structure and compact organization, Long service life purpose. The user has given a high evaluation of the slag pot products we delivered. The first four pieces were shipped recently. The user promised to establish a long-term cooperation relationship with our company.

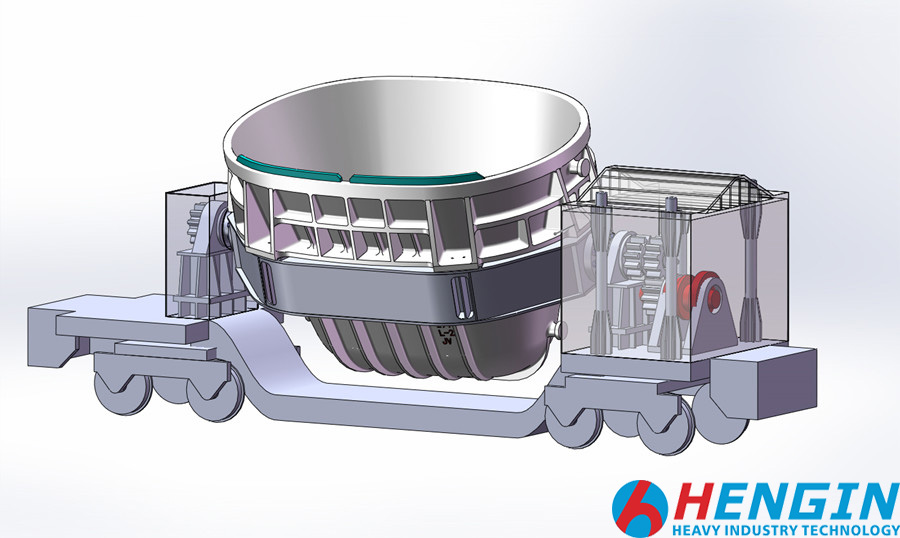

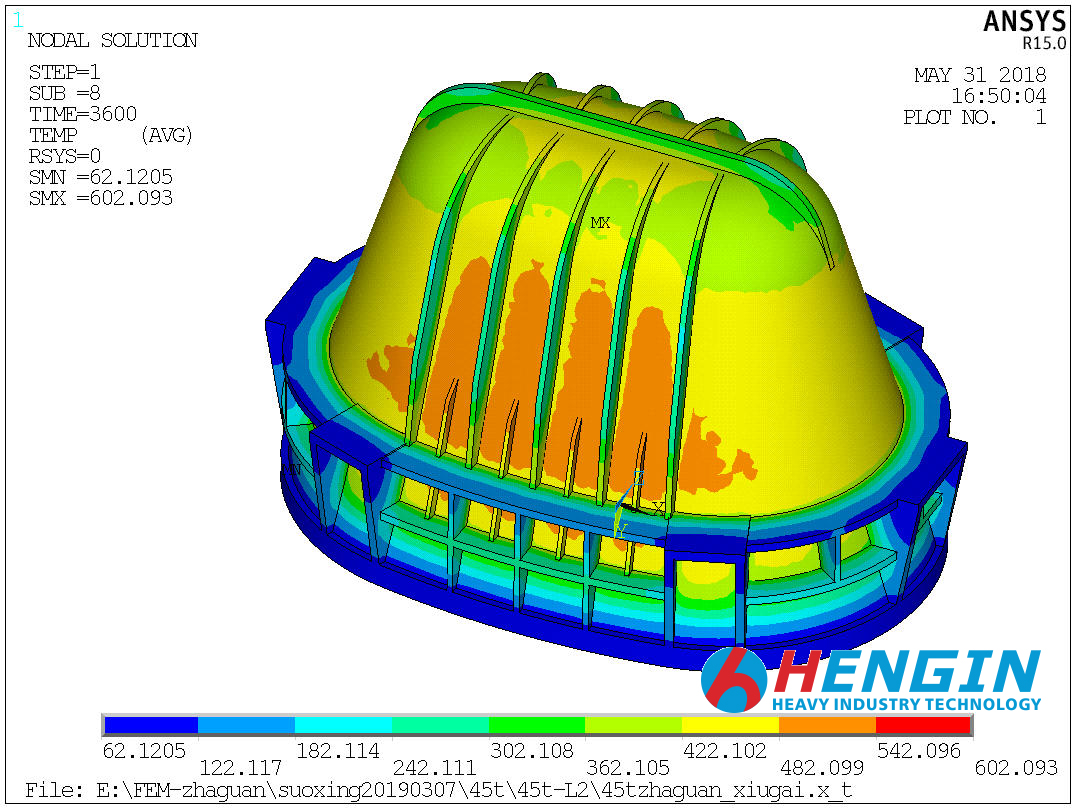

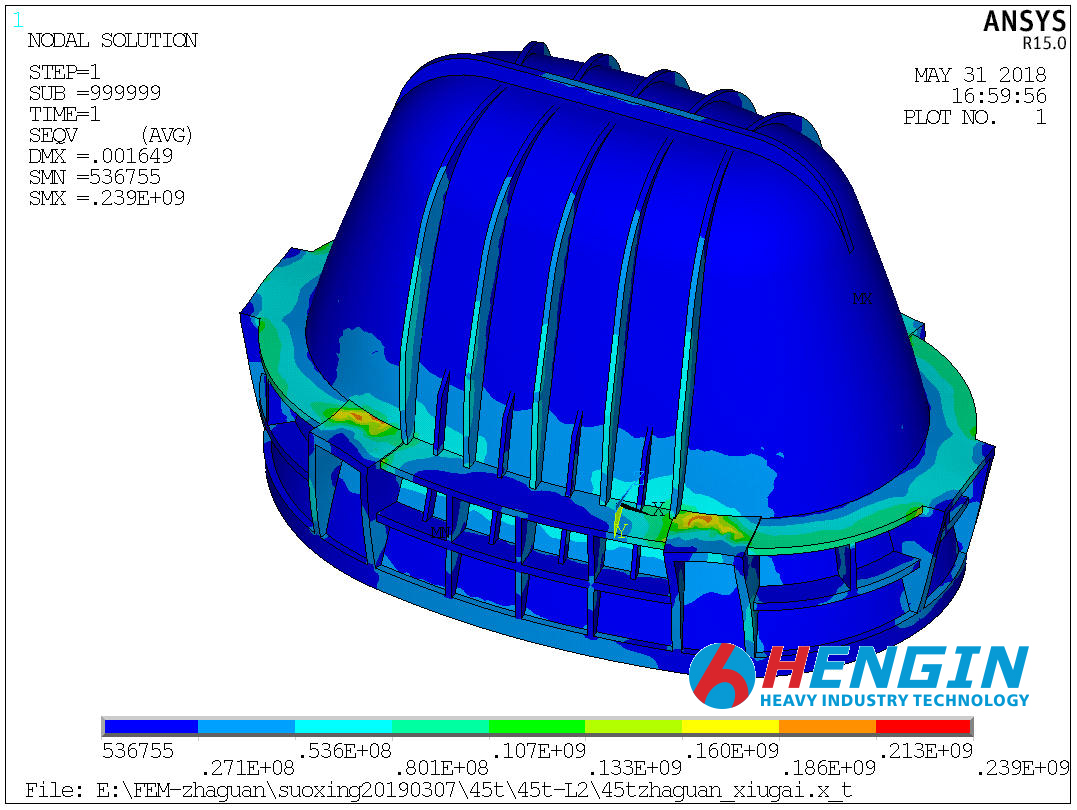

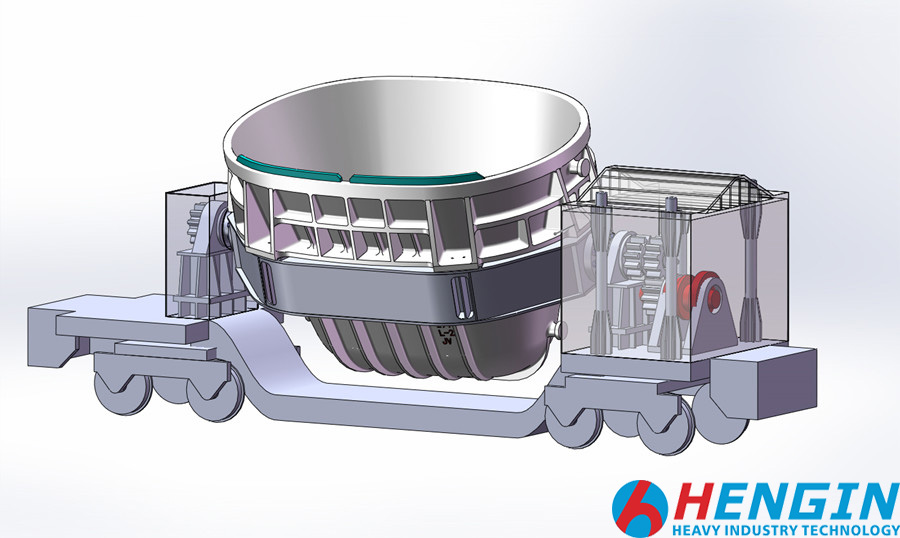

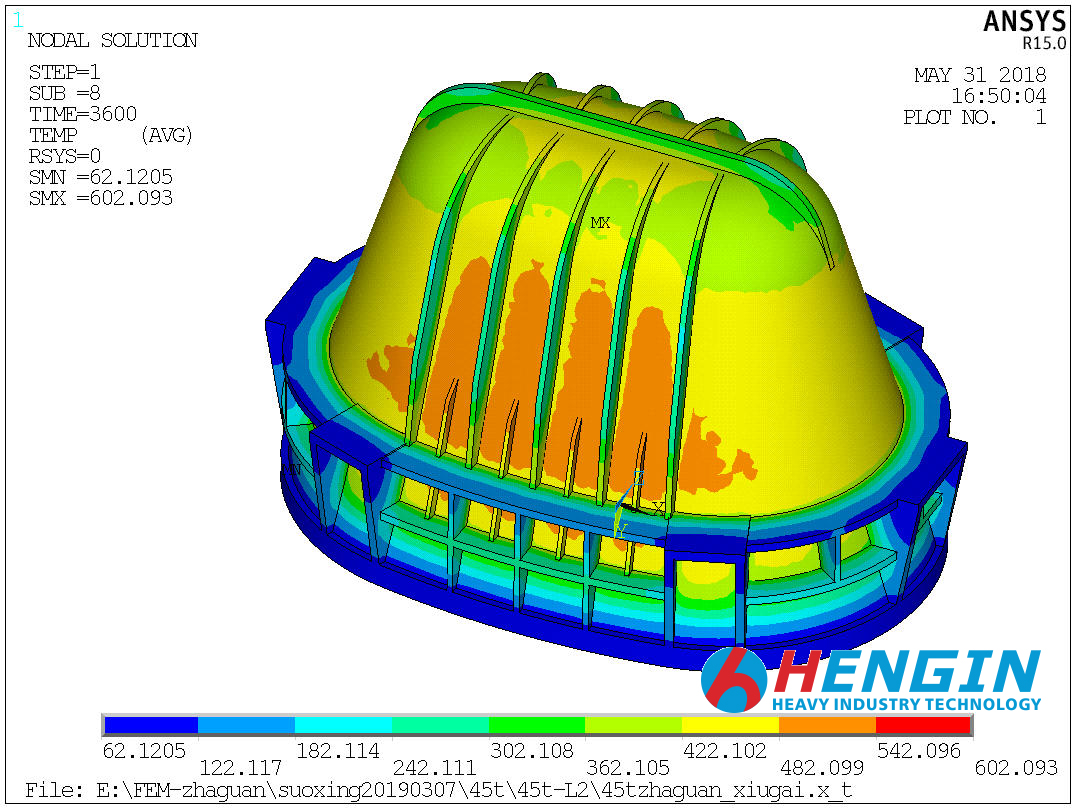

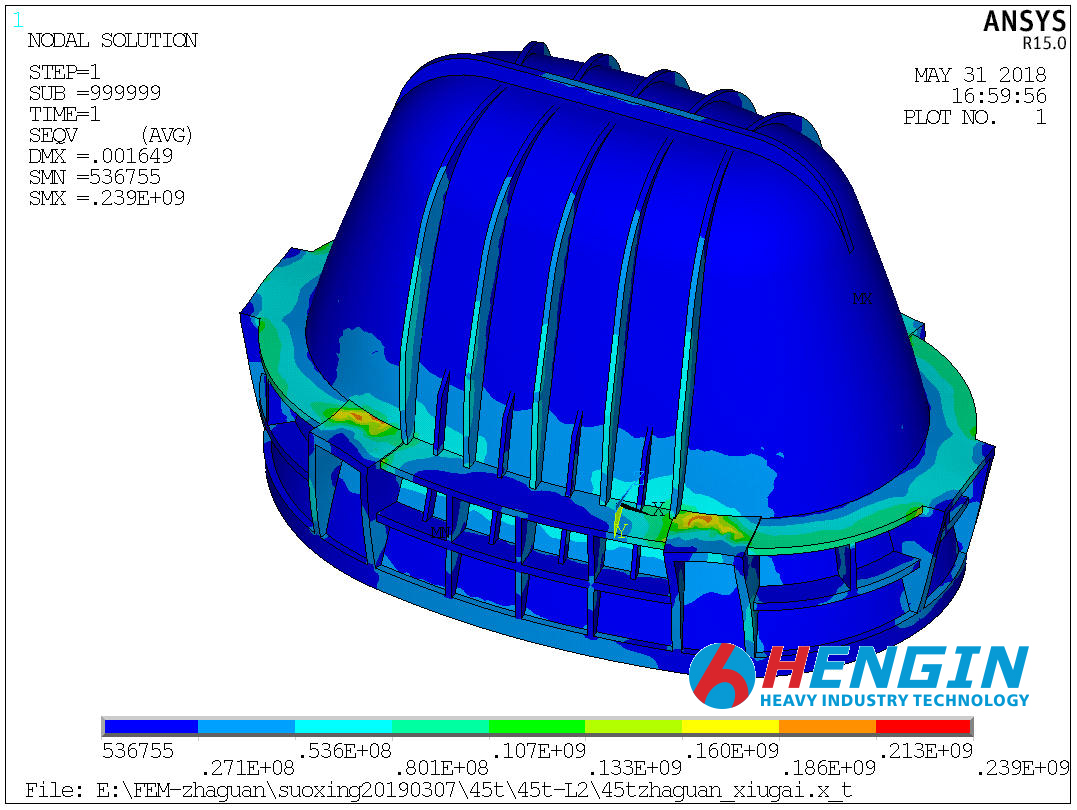

1.The volume of the slag pot is 25m3, the weight is 27.5t, and the maximum wall thickness is 140mm. Due to the large size, weight and wall thickness of slag pot, we use soliderworks to calculate and determine the key parameters such as the size of ellipse long and short axis, wall thickness, stress of trunnion, grid distribution of slag pot wall.

|

2.The volume of the slag pot is 25m3, the weight is 27.5t, and the maximum wall thickness is 140mm. Due to the large size, weight and wall thickness of slag pot, we use soliderworks to calculate and determine the key parameters such as the size of ellipse long and short axis, wall thickness, stress of trunnion, grid distribution of slag pot wall.

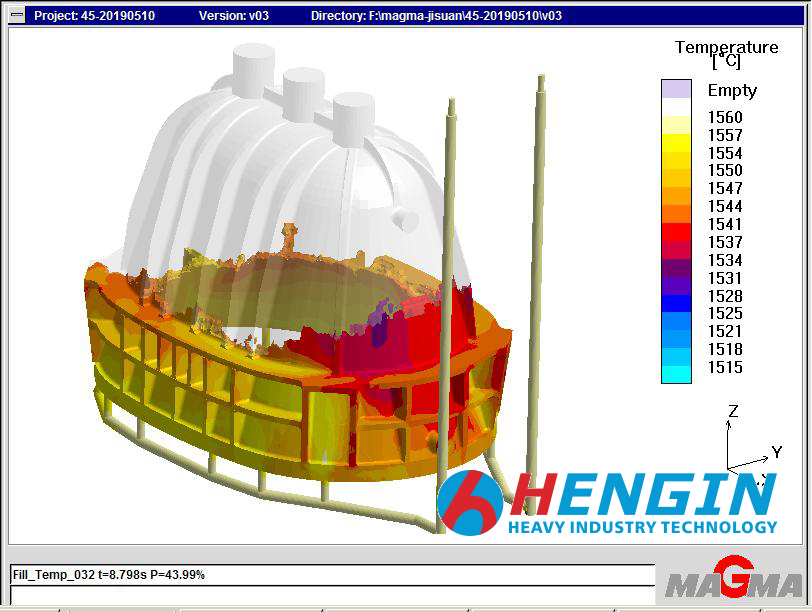

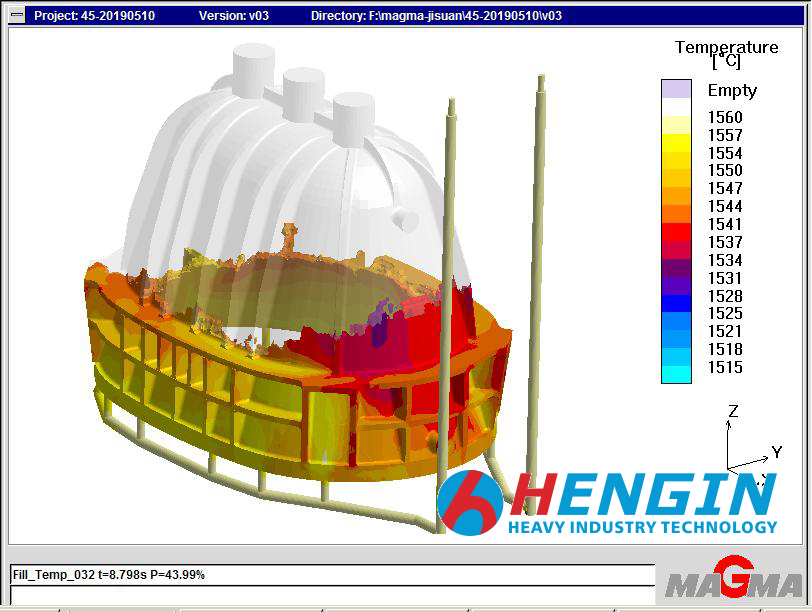

3.slag pot castings, especially large steel casting slag pots, are easy to produce shrinkage, shrinkage, segregation and other casting defects at thick and large hot joints, which seriously affect the quality of slag pot, resulting in the internal structure of slag pot is not compact, low strength, easy to produce cracks, fatigue, short service life and other problems. Therefore, we use MAGMA to eliminate casting defects and ensure the microstructure compactness to the greatest extent, Uniformity of composition and mechanical properties.

3.slag pot castings, especially large steel casting slag pots, are easy to produce shrinkage, shrinkage, segregation and other casting defects at thick and large hot joints, which seriously affect the quality of slag pot, resulting in the internal structure of slag pot is not compact, low strength, easy to produce cracks, fatigue, short service life and other problems. Therefore, we use MAGMA to eliminate casting defects and ensure the microstructure compactness to the greatest extent, Uniformity of composition and mechanical properties.

4.The delivery status of slag pot castings is smooth and smooth after shot blasting, without sand sticking, air holes, shrinkage holes, shrinkage and other defects, and the surface is polished without flash burr.

5.We carry out dimension test, chemical composition test, body sample mechanical test, NDT (NDT) and provide the customer with test report and attached cast sample for re inspection and verification. The ultrasonic testing standard is EN10160 grade 2, and the magnetic particle inspection standard is EN 1290 grade2. The results show that the size is accurate to the tolerance requirements of the drawings, the chemical composition of spectral detection meets the standards of synthetic partition, and the mechanical properties and NDT are up to the standard.

6.After planning the balance of loading force of slag pot, the truck will run smoothly and reach Shanghai port according to the scheduled time.

7.Slag pot ready for shipment

4.The delivery status of slag pot castings is smooth and smooth after shot blasting, without sand sticking, air holes, shrinkage holes, shrinkage and other defects, and the surface is polished without flash burr.

5.We carry out dimension test, chemical composition test, body sample mechanical test, NDT (NDT) and provide the customer with test report and attached cast sample for re inspection and verification. The ultrasonic testing standard is EN10160 grade 2, and the magnetic particle inspection standard is EN 1290 grade2. The results show that the size is accurate to the tolerance requirements of the drawings, the chemical composition of spectral detection meets the standards of synthetic partition, and the mechanical properties and NDT are up to the standard.

6.After planning the balance of loading force of slag pot, the truck will run smoothly and reach Shanghai port according to the scheduled time.

7.Slag pot ready for shipment