|

|

|

| Original AG Φ12.2×11m Mill Dischager Head Liner | Original Grate Liner | Original Refractory Window Grate Liner |

|

|

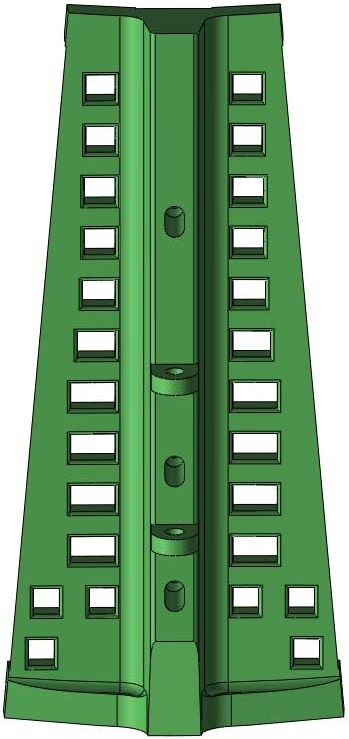

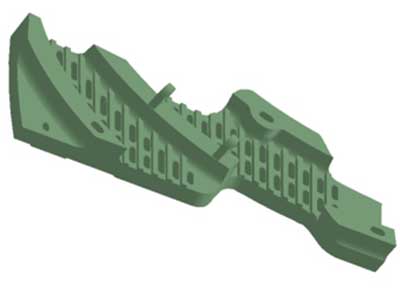

| New design of grid liner with spiral lifting strip structure-1 | New design of grid liner with spiral lifting strip structure-2 |

|

|

| Casting Of New Structure Grate Liner -1 | Casting Of New Structure Grate Liner -2 |

|

|

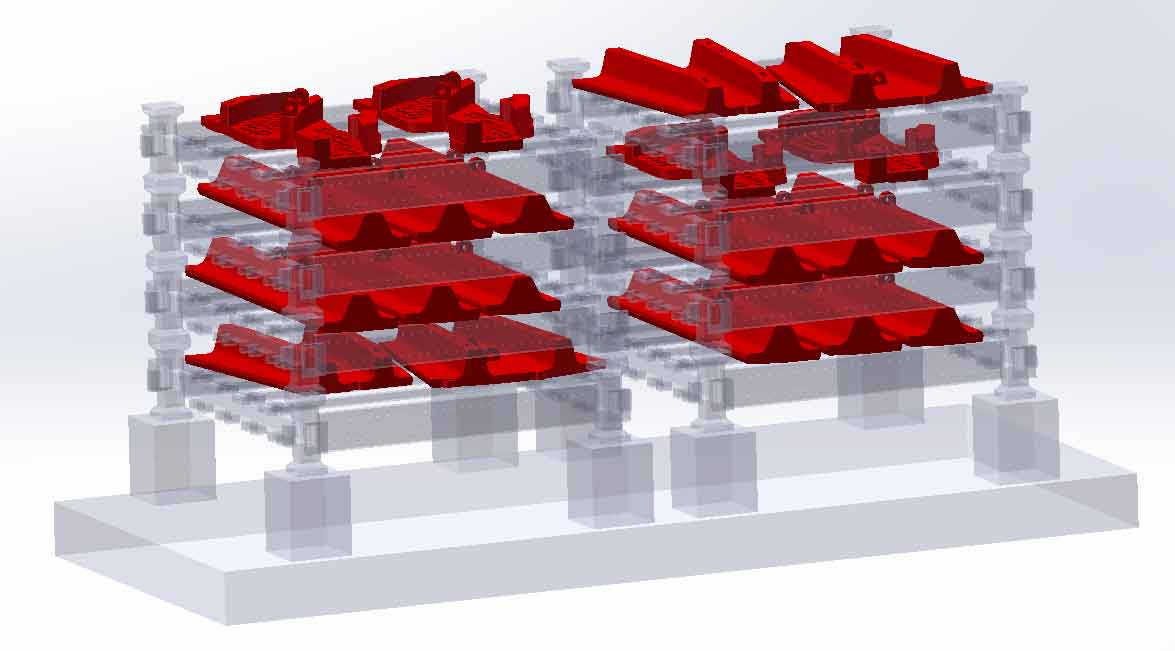

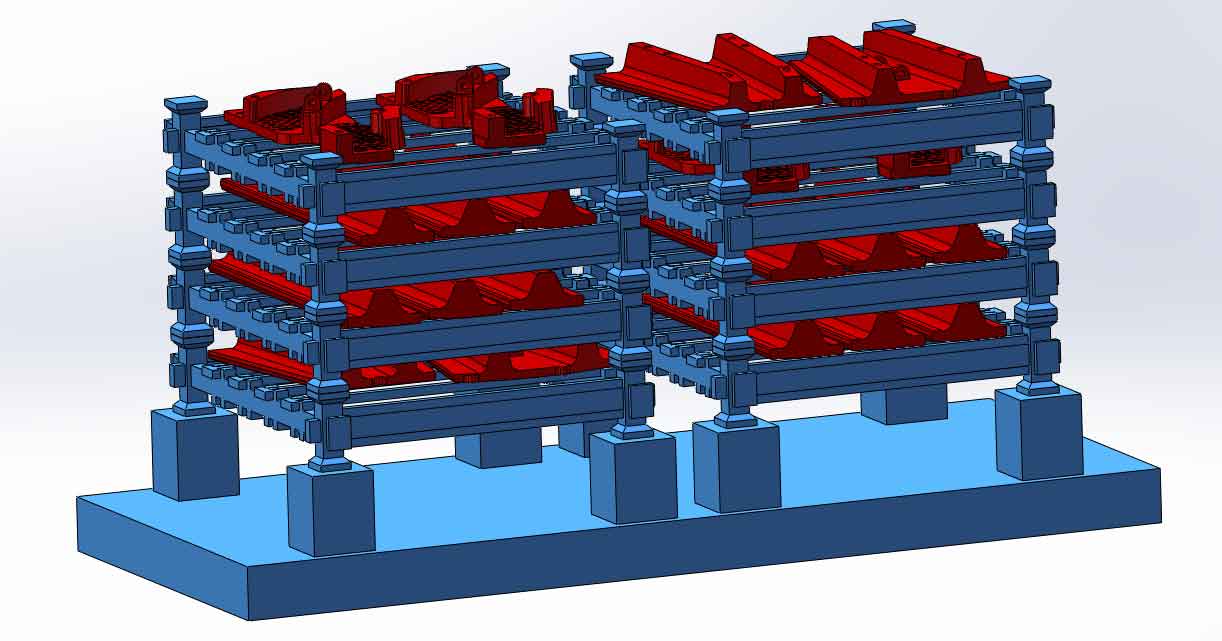

| Special Heat Treatment Tooling For New Structure Grate Liner-1 | Special Heat Treatment Tooling For New Structure Grate Liner-1 |

|

|

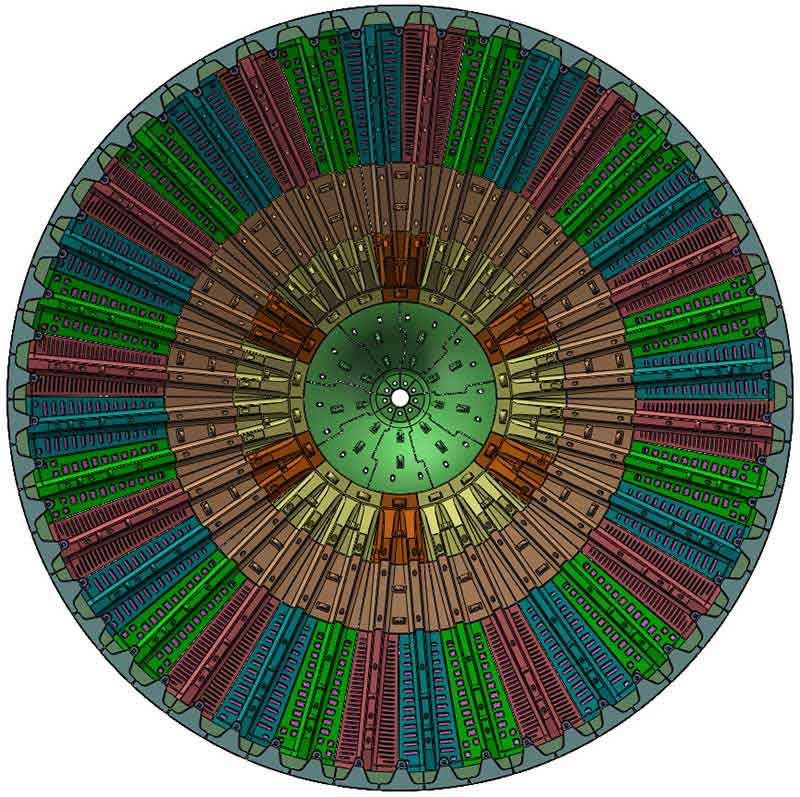

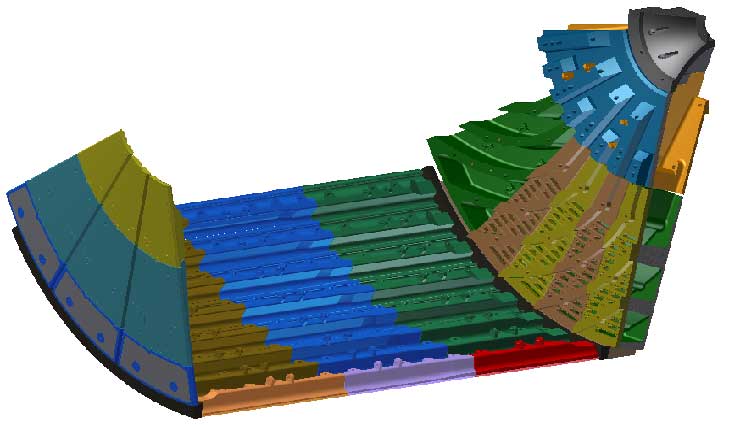

| Installation and Application Effect of New Structure Grate Liner-1 | Installation and Application Effect of New Structure Grate Liner-2 |