GP550 Bolw Liners-1

GP550 Bolw Liners-1

GP550 Bolw Liners-2

SYMONS7 FT Bowl Liners

Special Heat Treatment Equipment For High Mn Liner Of Crusher

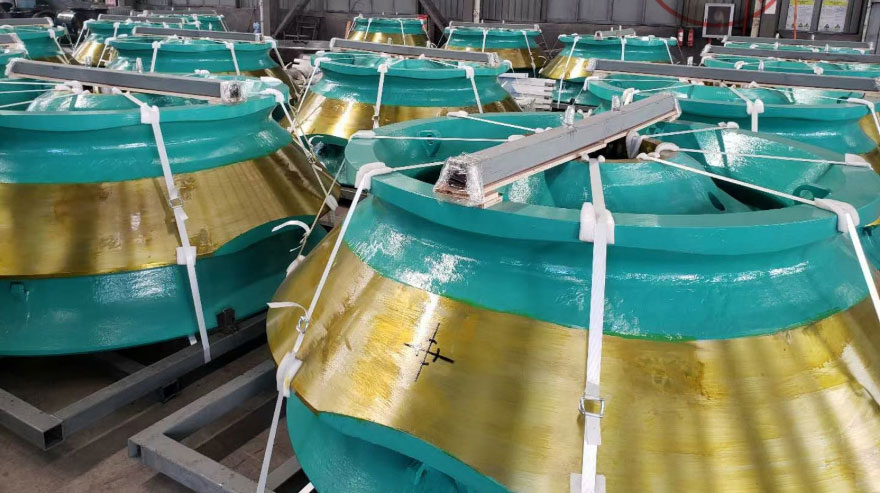

HENGIN provides 18 sets of GP550 cone crusher bowl liners and 10 symons 7ft bowl liners for a large copper mine and a large iron mine in South Africa. After 80 days of production cycle, they are packed and shipped to the port today. Since 2021, the global epidemic situation is still very serious. Due to the proper anti epidemic measures of the Chinese government and the effective guarantee of the normal life and production order, we have been able to complete the product manufacturing with high quality in a relatively short time, which has been recognized by customers. The supply quantity, weight and quality of this batch of crusher liners are the highest in hengin company. The accumulated experience and data of liner design, process design, quality control, testing and other links have laid a good foundation for us to develop and serve the wear-resistant parts market of mine crushers in the future. GP550 moving cone bowl liner weight 1218kg, fixed cone bowl liner 1687kg, 18 sets, a total of 52290kg. The maximum outer diameter of the bowl liner of symons 7ft cone crusher is 2311mm, and the single piece weight is 3246kg. Due to the large wall thickness, Mn18Cr2 material is used for this batch of liners.Therefore, we optimize the material composition, metallurgical process, casting process and heat treatment process to achieve the ideal effect.

Among them, Mo: 0.7-1.0%, V: 0.2-0.3%, Ti: 0.15-0.3%,Nb:0.03-0.06,Re: 0.1-03% are added for full alloying metallurgy. The main purpose is that the carbide in the microstructure is multi-component compound fine-grained carbide, which is tempered after water toughening treatment, so as to achieve precipitation strengthening, improve the initial hardness and yield strength of the liner, and make it have good strength, toughness and wear resistance.

In addition to the conventional process of refining the molten steel, the smelting of this batch of liners was also deoxidized with Zr and Al elements, and re was further deoxidized during tapping to remove the gas, reduce the number of inclusions, change the shape of inclusions, further refine the grains, and reduce the crack source of liners in use.

Our factory has improved the heat treatment equipment according to the process requirements, so that the liner can be quickly cooled in water after uniform temperature and heat preservation in the heat treatment furnace. In this way, the single austenite structure of Mn liner can be obtained at room temperature without decomposition, and the liner has excellent impact toughness.

Through the improvement and optimization of the above process technology, we expect that the service life of the liner will be increased by more than 20%. Hengin has always been highly standard technology and products to provide users with cost-effective services and create greater value for users.