Jaw Crusher Liner has a two-phase structure in the as-cast state, and the carbides are distributed on the austenite grain boundaries and are very fragile. The high manganese steel parts without heat treatment in the as-cast state have no use value. The jaw crusher liner can only exert its excellent performance when it is used after proper heat treatment so that the carbides are completely dissolved in the austenite. The heat treatment of high manganese steel is called quenching, also known as austenitizing heat treatment or solution treatment. Generally, the quenching of high manganese steel is carried out in water, so it is also called water toughening treatment.

To prevent fatigue fracture during the use of the jaw crusher liner, the first is to eliminate the nucleation sources that produce crack nucleation. These nucleation sources are formed by the dendrites developed during the solidification of the casting to prevent the liquid from shrinking. Therefore, grain refinement is a means to prevent cracks; secondly, due to the large mass of the jaw crusher liner , a large amount of latent heat of crystallization is generated, which results in a large amount of carbide precipitation, and in the subsequent heat treatment process, the carbide dissolves into the Austrian In the case of austenite, leaving holes in the original position of the carbide, the holes will become the nucleation source of cracks. Low carbon content, low-temperature casting and grain refinement can effectively prevent this defect; the third is the phosphorus eutectic on the grain boundary, non-metallic inclusions, shrinkage and shrinkage are all sources of crack nucleation . Strengthening the deoxidation and dephosphorization of molten steel can effectively prevent phosphorus eutectic, non-metallic inclusions, shrinkage and shrinkage.

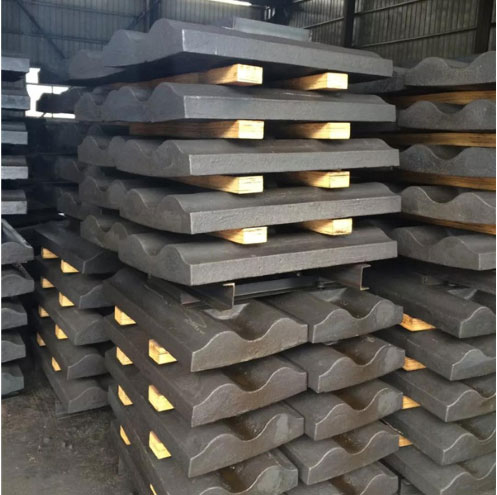

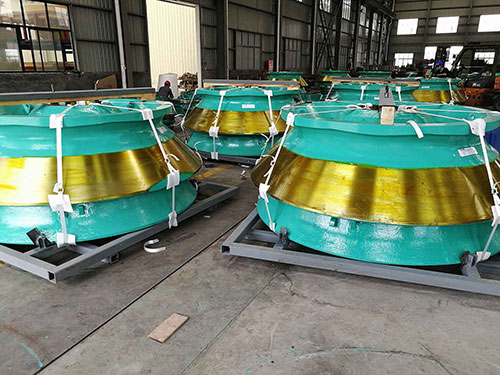

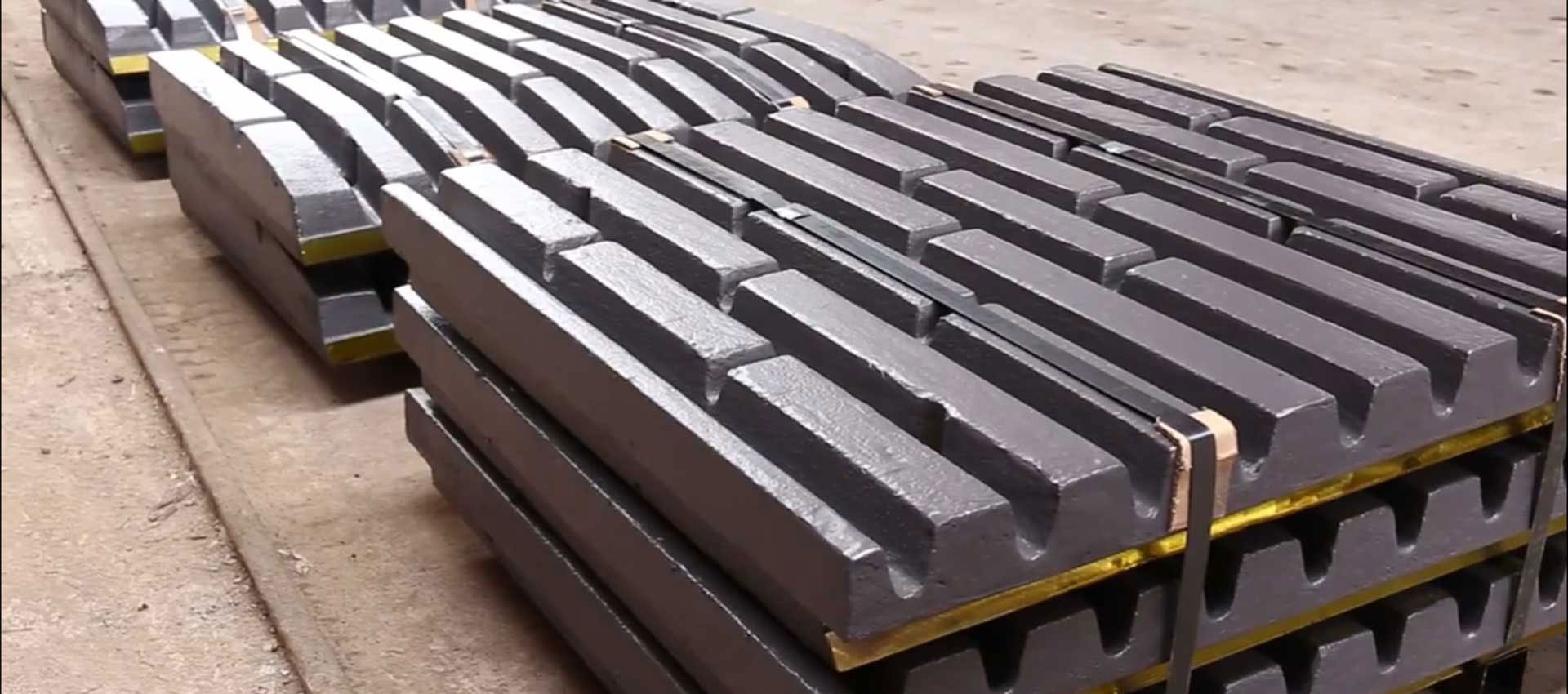

■ HENGIN OEM Jaw Crusher Liner includes the following series

◆Metso C Series ;

◆Sandvik CJ series ;

◆TRIO CT Series ;

■ Material

Mn13Cr2,Mn18Cr2,Mn20Cr2,Mn13Cr2Mo,Mn18Cr2Mo,Mn20Cr2Mo;

Jaw Crusher Liners can cast inlaid carbide rods to increase service life.

■ Weight Range

500-20000kg;

■ Manufacturing Process Flow

process design, model making, casting, water toughening heat treatment, machining, packaging;

■ HENGIN'S Jaw Crusher Liners Advantages

casting process design uses Procast for simulation and solidification simulation to eliminate shrinkage and shrinkage casting defects; molten steel smelting for refining eliminates gas and inclusions, reduces component segregation, reduces the generation of micro-cracks, improves the liner Wear resistance.