Girth Gear Casting Simulation Analysis

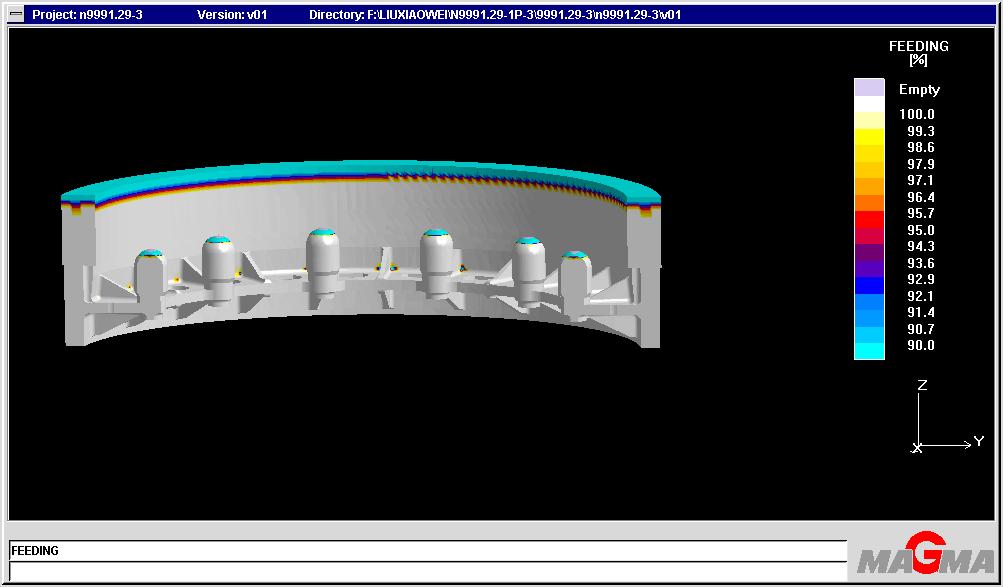

■ The main purpose of simulation of girth gear ring casting by simulation software is to prevent the occurrence of casting defects and timely adjust the process parameters to eliminate the possibility of shrinkage cavity and shrinkage pine.

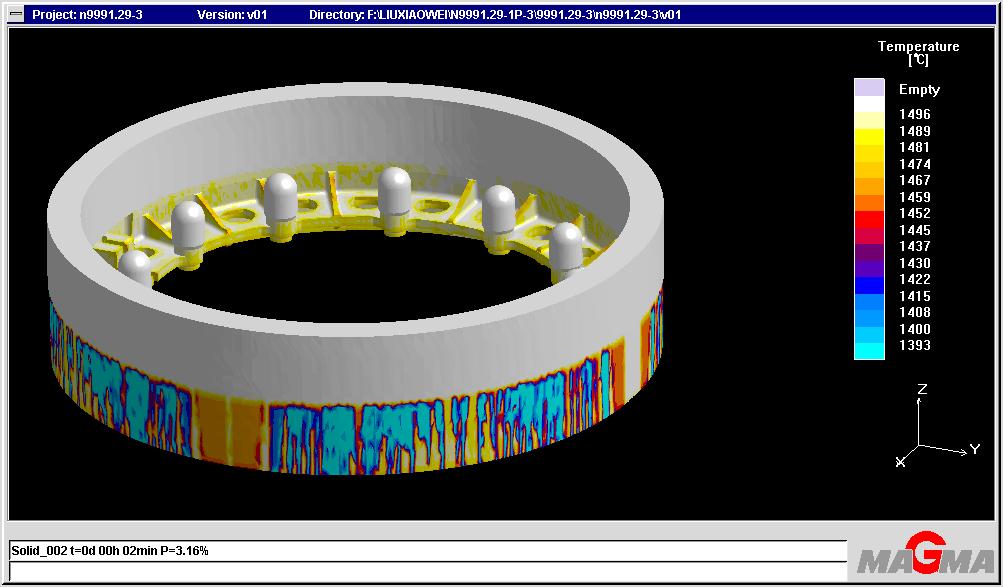

■ Through the simulation, the stamping process of molten steel can be observed to prevent the turbulent flow due to unreasonable design of the pouring system and to avoid the defects of slag inclusion and sand inclusion, which can strictly control the pouring time of molten steel to ensure the appearance quality of the casting.

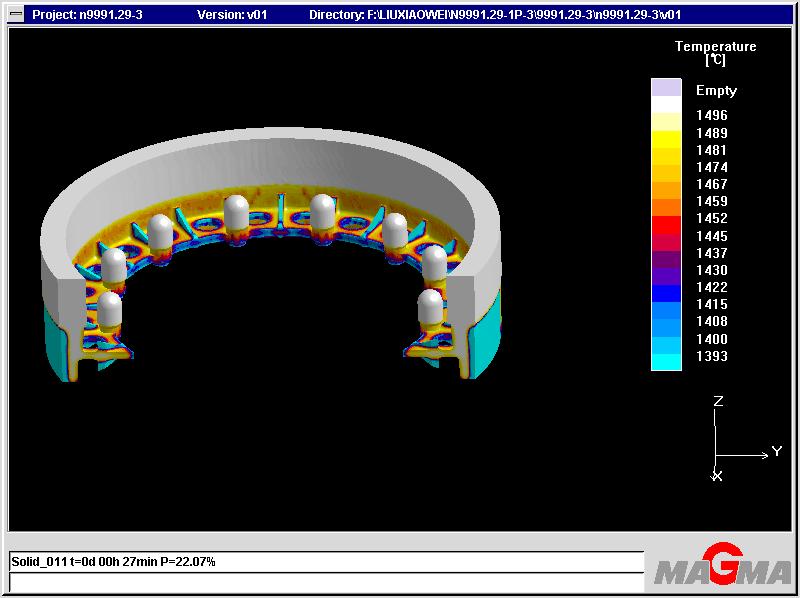

■ We can observe and analyze the variation of temperature field distribution of castings, adopt cooling method and make the temperature field distribution uniform to avoid the occurrence of casting defects, large casting stress and coarse grains due to uneven temperature distribution.