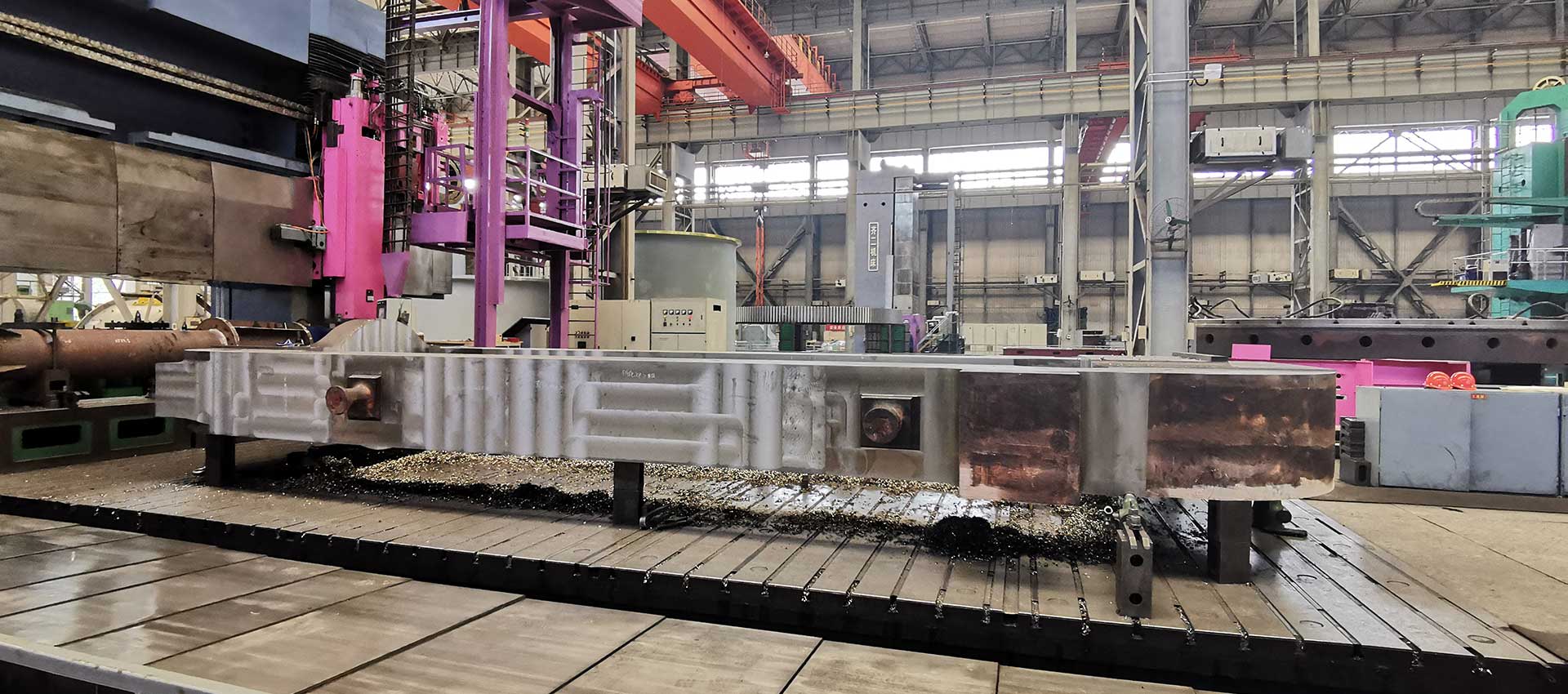

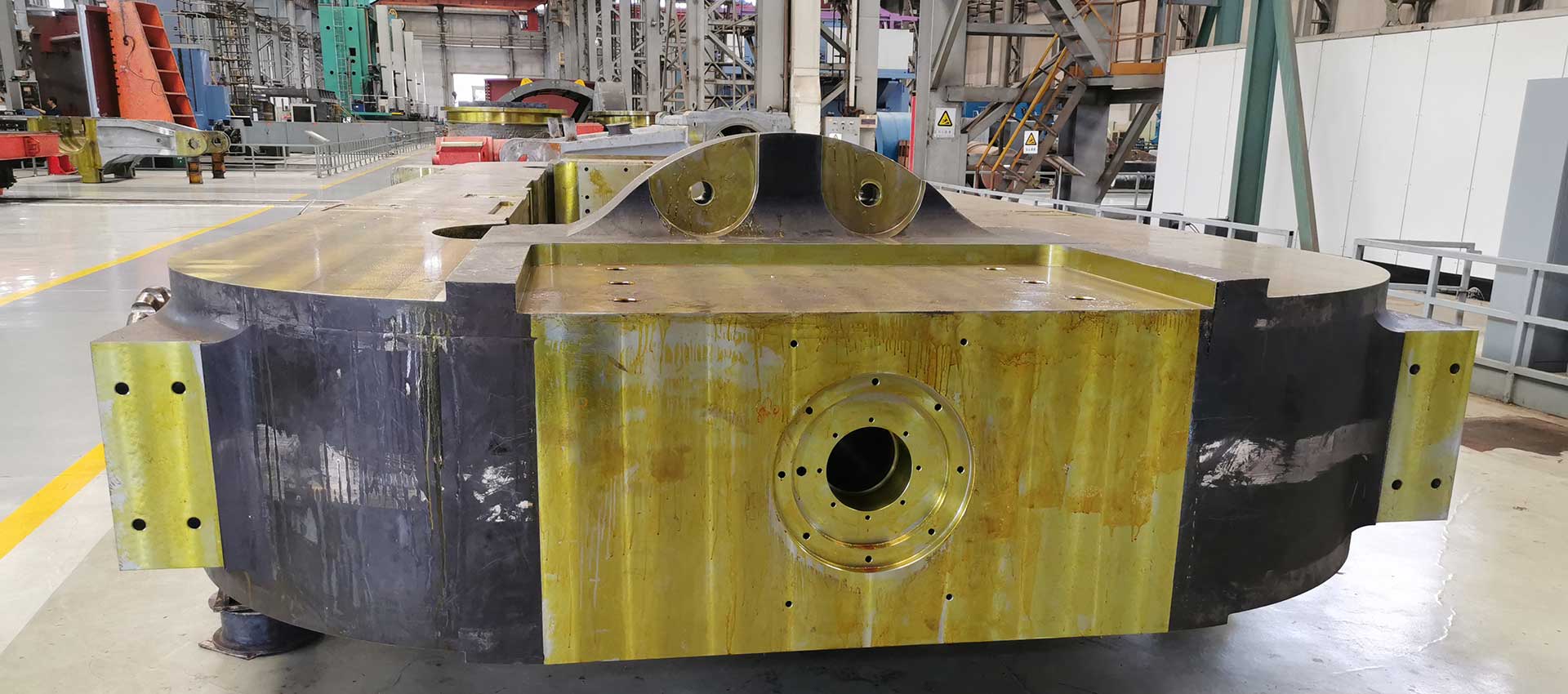

Rolling Mill Housing is a key bearing component on the rolling mill. It has a complex shape, a large body load and high quality requirements. Castings must not have casting defects such as inclusions, shrinkage holes, looseness and cracks. Roller bearing seat and roller adjusting device are installed in the wheel arch.Therefore, mill housing mechanical performance requirements are also very high.

■ Rolling Mill Housing Types

2 roll mill,3 roll mill,4 roll mill,5 roll mill,6roll mill,Multi-roll mill

■ Rolling Mill Housing Material

GS20-Mn5v,GS240,BS3100A2,ZG42CrMo,ZG270-570 and other materials and properties according to customer requirements.

■ Manufacturing Process

Casting → Roughing → Flaw Detection (defect treatment) → Heat Treatment (stress relief) → Semi-Finishing (boring and milling machine processing) → Secondary Overall Flaw Detection → Finishing → Inspection → Finishing (blasting, arc gouging, etc.) → Painting.

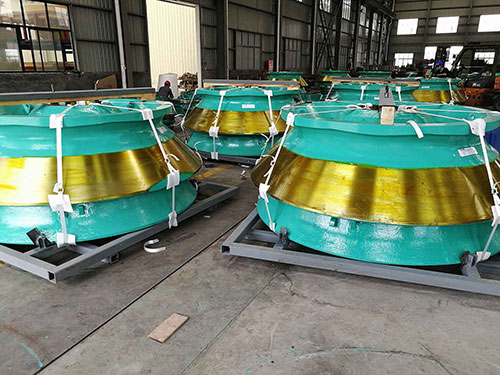

■ Rolling Mill Housing Casting

◆The casting process design uses Procast to simulate, eliminating the internal shrinkage and shrinkage defects.

◆The molten steel is refined outside the furnace, and the molten steel is more pure, reducing harmful factors such as slag inclusion and gas.

■ Weight:5t-100t.