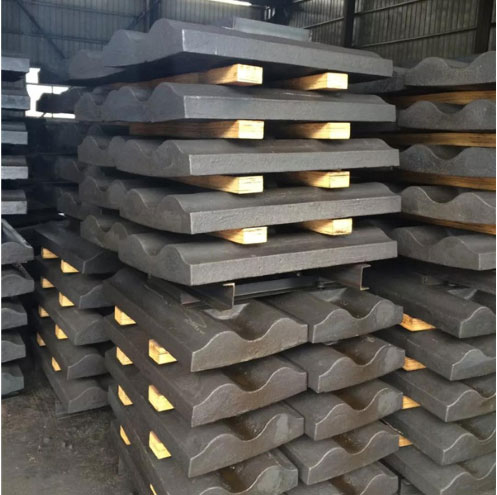

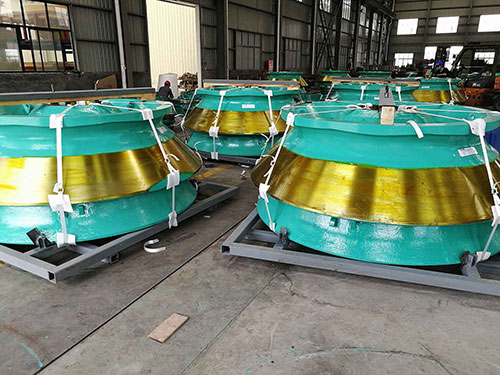

■ Rotary kiln Block Roller structure: The rotary kiln hydraulicBlock Roller is used to limit (ordinary Block Roller) or control (hydraulic Block Roller) the axial movement of the kiln body. Under normal circumstances, a certain distance must be maintained between the retaining wheel and the side of the belt. The value of this distance is determined according to the allowable axial running distance of the kiln shell. The principle for determining the spacing is to not only wear the wheel belt and the supporting roller evenly across the full width, but also make the gears on the kiln mesh well, and at the same time, the sealing devices at both ends of the kiln will not lose the sealing effect.

■ For rotary kilns with multiple supports, due to the thermal expansion and contraction of the kiln body, the retaining wheel is generally arranged on both sides of the belt near the transmission gear ring. This not only prevents the excessive axial movement of the large ring gear from affecting the meshing, but also facilitates the design of the large and small gear cover. Common ones are ordinary Block Roller and hydraulic Block Roller.

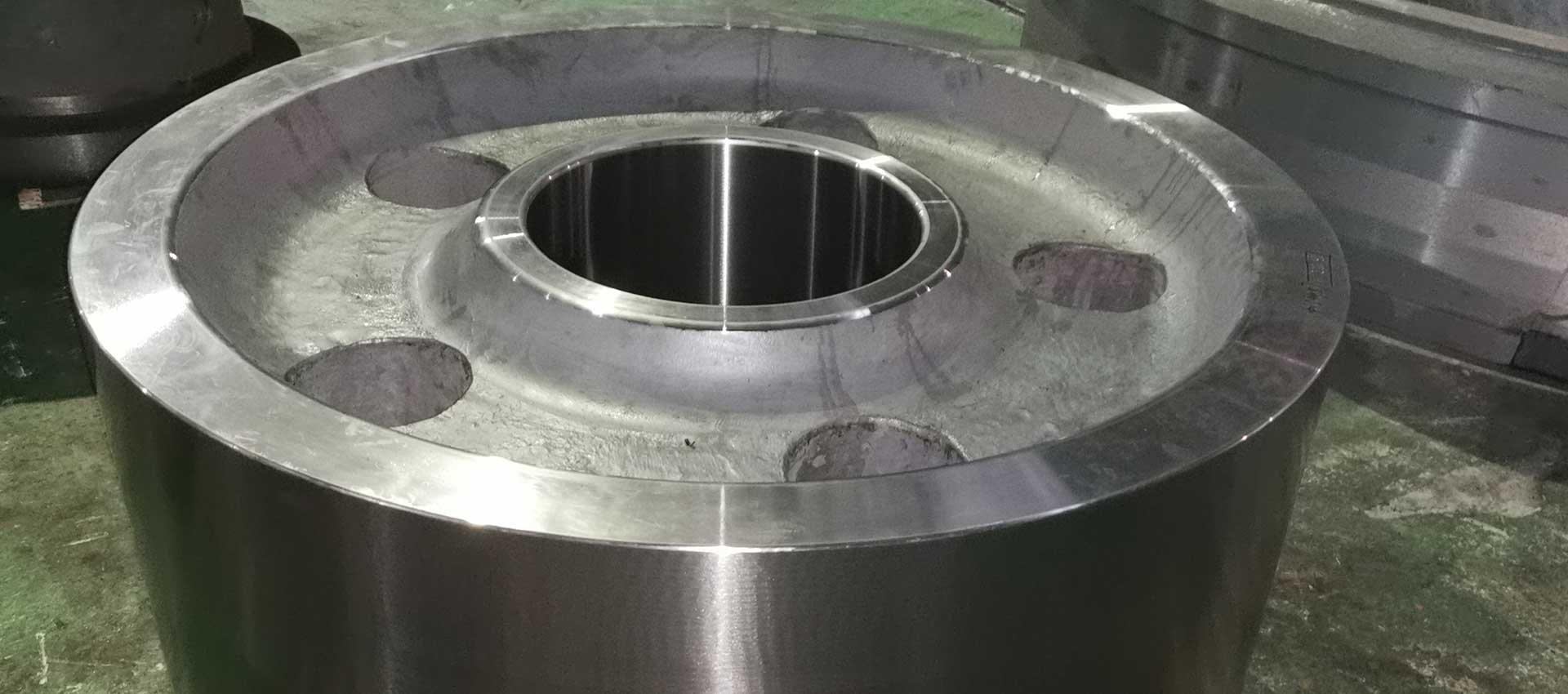

■ The editor of the machinery in the mine focuses on the structure of the hydraulic Block Roller of the rotary kiln.

Hydraulic Block Roller is usually used in large-scale rotary kiln. It has the advantages of low energy consumption, uniform operation, and guarantee the linearity of the kiln body. Hydraulic gear wheel structure.