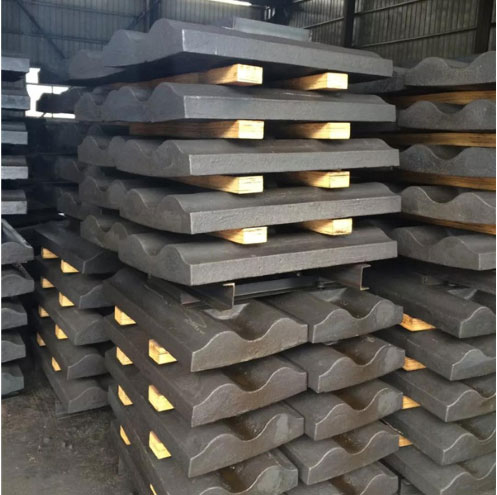

■ Inspection standard for Slag Pot manufacturing

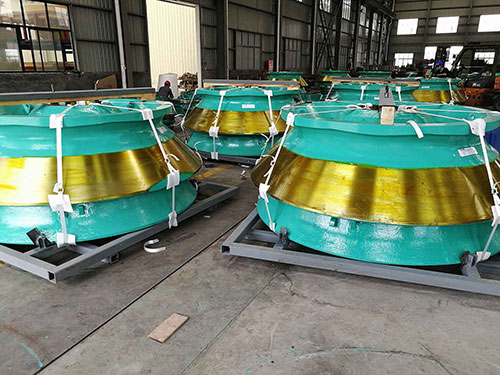

◆ The coaxiality and dimensional accuracy of the trunnion of slag can and the overturned trunnion of slag can shall be ensured when the slag can is overturned by the can holding machine.

◆ The surface of the tank shall be smooth, and the non machined surface shall be free of visible casting defects such as shrinkage porosity, air hole, crack, slag inclusion, etc.

◆ Slag Pot castings shall be provided with body samples, and the Demander shall recheck the chemical composition and mechanical properties.

■ Material:ZG20RE,GE240,B2,EN-GJS-400-18,EN-GJS-500-7,EN-GJS-600-3.

■ Chemical Composition and Smelting Control

Although the material of large-scale cast steel is different and the calibration range of some elements is large, through our mathematical statistics and analysis, each element has certain influence on the solidification shrinkage, crack formation and service life of the . The following principles are required for the composition control of large-scale cast steel :

◆ The fluctuation of carbon content shall be controlled within 0.05%;

◆ The manganese content shall be controlled within the upper limit of the range;

◆ The harmful elements of sulfur and phosphorus shall be controlled within the lower limit of the range;

◆ The alloy elements shall be controlled within the middle limit;

◆ On the basis of current EAF smelting, the ladle shall be modified to carry out argon blowing refining of molten steel to achieve the purpose of purifying molten steel.