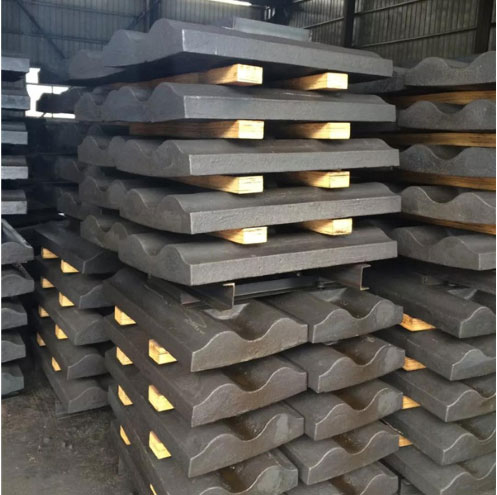

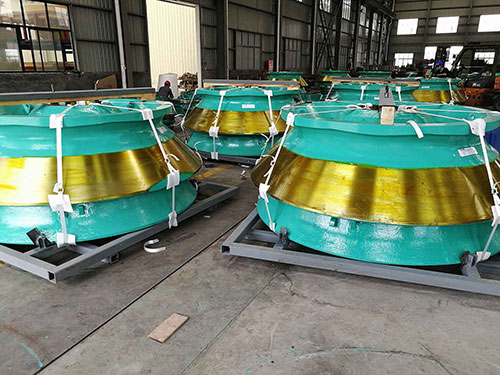

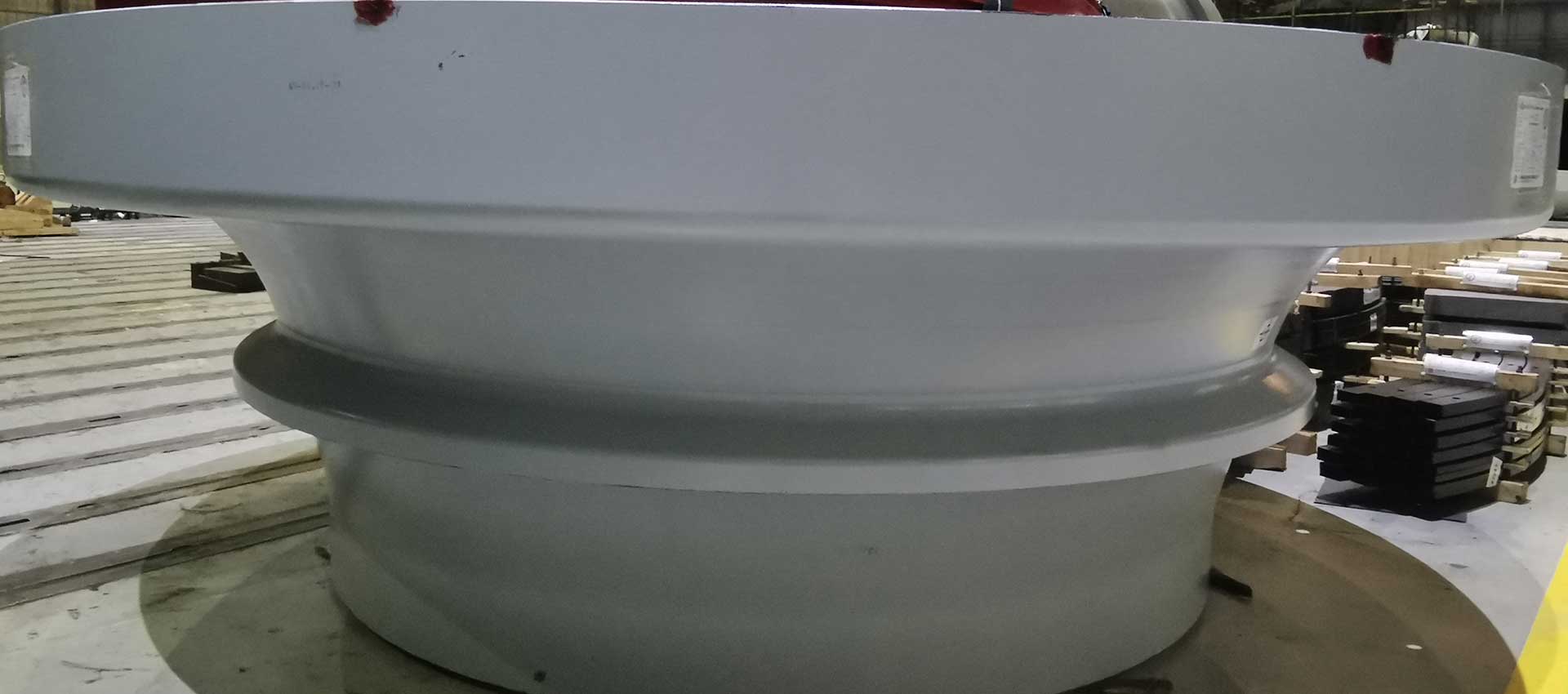

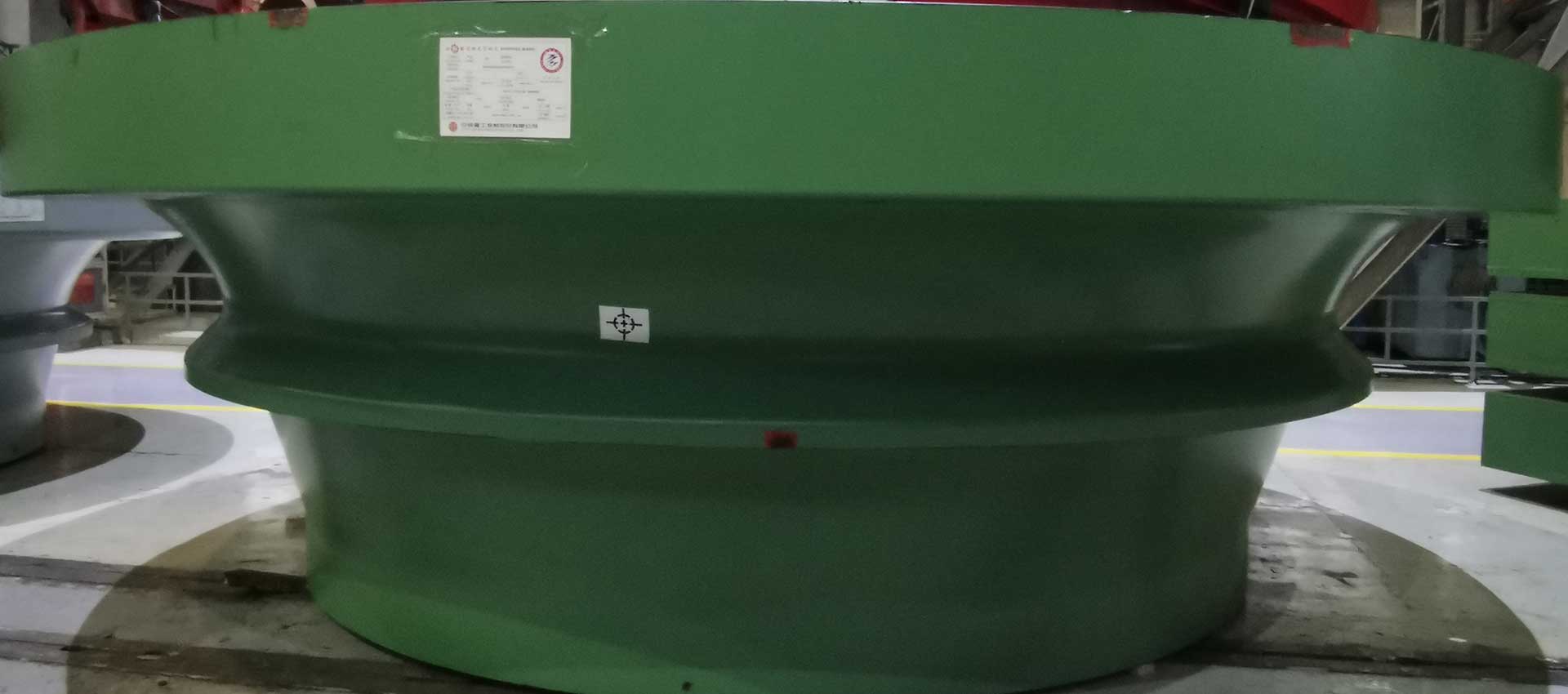

Grinding Table is one of the main grinding components of the roller mill. The main function of the grinding table is to support the material bed, transmit the force generated by the grinding roller to the lower reducer, and transmit the torque of the reducer to the grinding area. After the material falls on the dispersing plate, due to the effect of centrifugal force, it spreads evenly around and enters the grinding area between the grinding roller and the grinding table for grinding. As the production capacity of the cement production line increases, the size of the grinding table as a large casting is getting larger and larger, and the weight is increasing.The heavier, the larger grinding table put forward higher requirements on materials, casting process design and machining ability. HENGIN has mature material, casting, and machining experience, and has accumulated rich parameters, can manufacture large-scale high-quality ductile iron and cast steel grinding table.

■ Manufacture Method: Casting, Machining.

■ Material: QT400-15A,ZG270-450.

■ Weight: 10-142t.

■ Wall thickness: 200-400mm.

■ Spheroidizing treatment: RE Mg spheroidizing.

■ Heat treatment: normalizing + tempering.

■ Brand: CITIC, HENGIN.