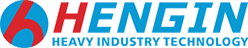

■ Manufacturing process: casting, heat treatment, machining, non-destructive testing;

■ Casting: resin sand modeling, intermediate frequency furnace smelting, refining outside the furnace;

■ Heat treatment: normalizing + tempering, normalizing adopts spray cooling;

■ Matrix structure: martensite + carbide;

■ Hardness: HRC≥58

■ Service life: more than 8500 hours;

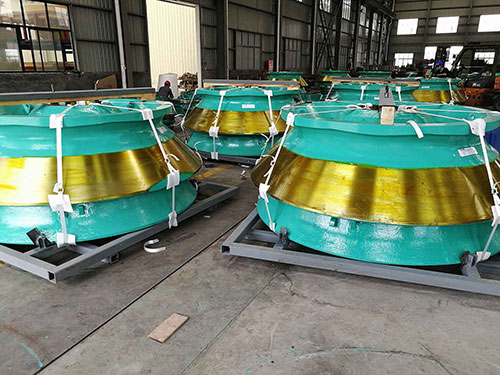

■ Brand and model of cement vertical mill

|

|

|

|

|

|

HRM1300 |

UM46.4SN |

|

|

HRM1500 |

UM50.4 |

|

|

HRM1700 |

UM35.3 |

|

|

HRM1900 |

UM56.4 |

|

|

HRM2200 |

UM46.4SN |

|

|

HRM2400 |

UM38.4 |

|

|

HRM2800 |

UM14.20D×2 |

|

|

HRM3400 |

UM46.4×2 |

|

|

HRM3700 |

UM50.470×2 |

|

|

|

UM46.4SN X 2 |

|

|

|

|