1. Roller material standard and inspection standard

When the roll body adopts integral forging, when the width of the roll is greater than or equal to 400 mm, the material used is not less than 34CrNiMo; when the width of the roll is less than 400 mm, the material used is not less than 45 steel in GB699. For split hot-packed extrusion rolls, the material selection of roll shaft is not less than 42CrMo steel, the material selection of roll sleeve is not less than 20Mn, the forging ratio of roll body is not less than 3, the forgings are quenched and tempered after rough processing, the forgings meet the requirements of JB/T1265, and the ultrasonic testing meets the requirements of JB/T5000.15-2007 grade III.

2. Overall performance requirements of rollers

The hardness of the roller sleeve is above 55 HRC, and the hardness of the column nail contacted with ore is no less than HRC65. The service life of roll surface is not less than 8000 hours when the grinding compressive strength is not less than 180 MPa brittle particulate matter or iron concentrate powder.

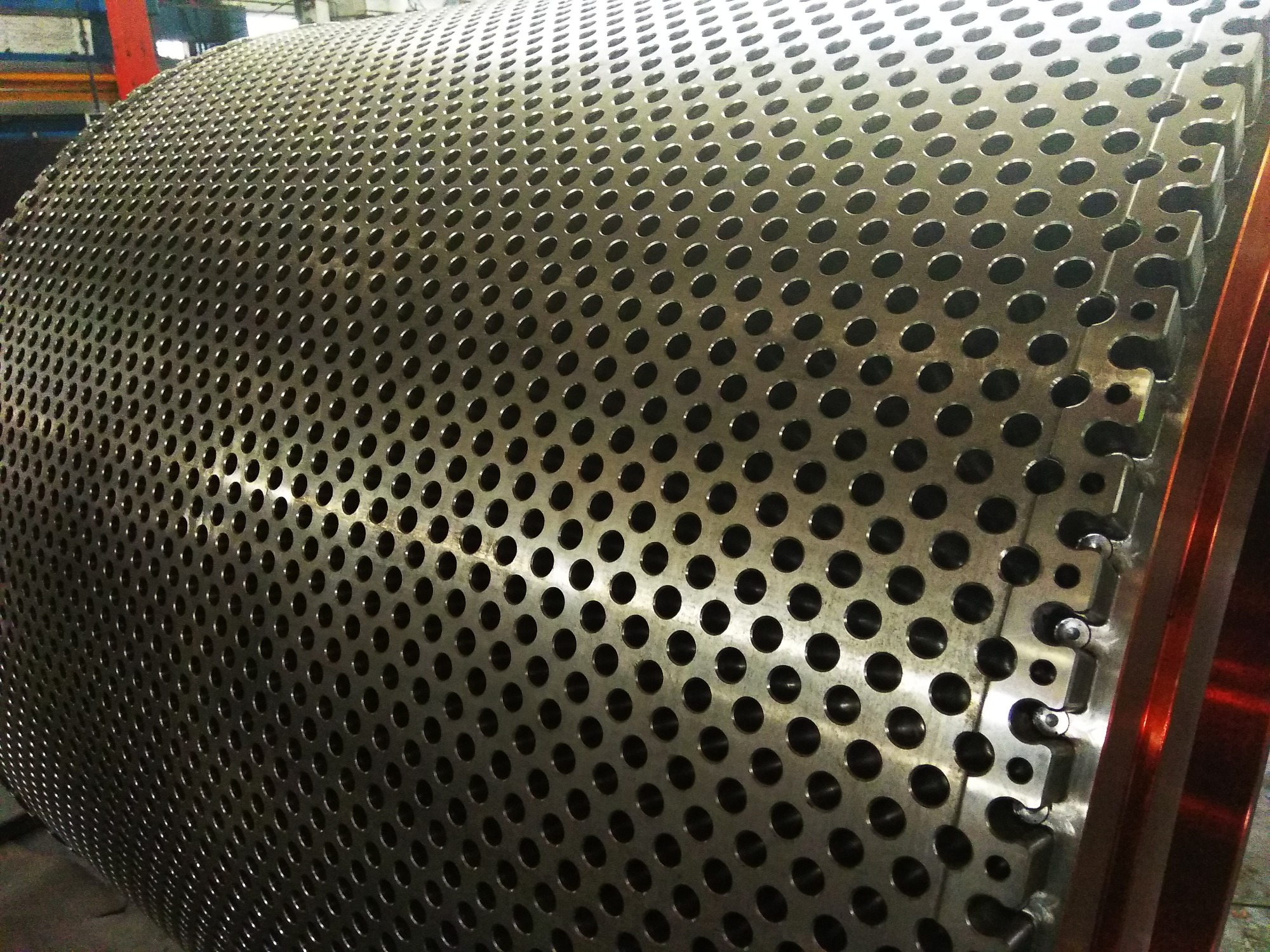

3. Superiority of Cemented Carbide Pillar Nail Roller

Roller press can increase the production efficiency of crushing system by 30% - 400%, and reduce energy consumption by 20% - 30%. When the roller press is working, two extrusion rolls moving in opposite direction produce huge extrusion force under the action of hydraulic system, which crushes the material. At this time, the roll surface needs to bear 50-300 MPa pressure, which produces strong friction with the material, and is subject to the impact of the material. The roll surface is very easy to wear. However, due to the two opposite rotating extrusion rolls of the high-pressure roll mill under the action of the hydraulic system, the material will be crushed. Because the high-pressure roller mill uses the pin roller surface, when working, the extrusion roll surface forms a layer of mattress, which plays a role in protecting the roll surface and slowing down the wear rate.

4. Roller cemented carbide stud material and manufacturing process

The material of cemented carbide studs belongs to tungsten-cobalt cemented carbide. Tungsten-cobalt cemented carbide is a kind of wear-resistant material with high hardness, high strength and good impact resistance, which is prepared by powder metallurgy process using tungsten carbide as matrix and cobalt as bonding phase. The hardness of tungsten carbide is almost the same as that of diamond, so the hardness of the alloy is very high. As a binder phase, cobalt makes the alloy dense after sintering at high temperature, and has high toughness, which enhances the flexural strength and impact strength of the alloy. The column nail and the hole of the column nail are fitted in clearance, and the hot-charging temperature is fixed by glue at not less than 180 C. The service life of cemented carbide column top varies from 8000 to 30000 hours according to different working conditions. The excellent wear resistance and impact resistance of tungsten-cobalt cemented carbide make the roll press more adaptable and its application field expanded.

5. Specification and properties of roll cemented carbide studs Table 1

Diameter

(Ф)mm |

Height

(H)mm |

Hardness

g/cm3 |

Hardness

/HRA> |

Flexural strength

/Nmm2 |

Applicable working conditions |

| 20 |

40 |

13.9-14.1

13.9-14.2 |

86.1

87.8 |

2800

2900 |

High wear resistance, suitable for

Iron ore, medium hard ore crushing

Highstrength adapts to

Crushing of Hard Ore

|

| 20 |

30 |

| 20 |

35 |

| 16 |

55 |

| 16 |

50 |

| 16 |

45 |

| 16 |

40 |

| 16 |

40 |

| 16 |

40 |

| 16 |

35 |

| 10 |

20.5 |

| 10 |

22 |

| 10 |

22 |

| 8 |

20 |