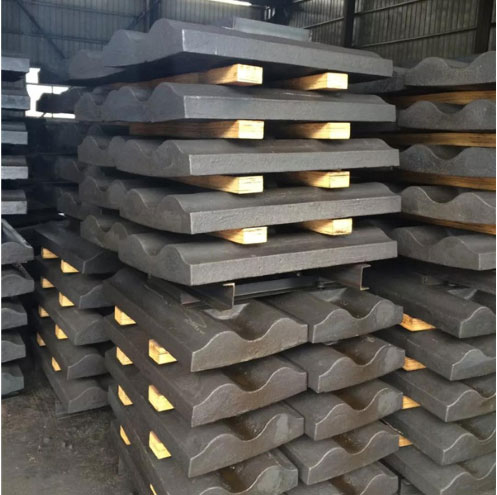

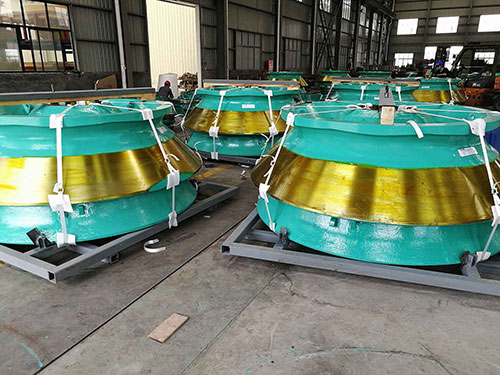

Copper Alloy Bearing Bush and screw nut are used as protective devices for main transmission parts of mill main bearing, crusher main shaft, rolling mill screw down device and cement rotary kiln support, which can reduce sliding friction and power loss in operation, increase service life of wear-resistant parts and reducmaintenance and maintenance costs. Strive for higher utilization rate of equipment; Effective protection against wear and tear of steel parts in contact with it, and easy replacement after wear and tear of copper parts. Copper tile and copper sleeve have certain strength, wear resistance, corrosion resistance and lubricity. They play an important role in the normal operation of equipment and are widely used in mining, cement, metallurgy and other fields. According to the chemical composition of cast alloy, it can be divided into the following categories:

The volume shrinkage of tin bronze Cu-Sn alloy is very small (linear shrinkage is 1.45%-1.5%). It is easy to make complex castings with accurate size requirements. Zinc, lead and phosphorus are usually added to cast tin bronze. Phosphide has high hardness, wear resistance and good abrasiveness. The definition standard of lead bronze sleeve is cast copper alloy with tin content less than 15% and lead content more than 6%, also known as high lead tin bronze. Lead bronze is usually used to make bearings and bushes.

■ Type of equipment used for HENGIN Copper Alloy Bearing Bush:

Metso, Jeffron, CITIC, NHI Grinding Mill, Metso, Sandvik crushers,

■ Copper Alloy Bearing Bush Material Type:

Tin bronze, lead bronze, brass and other materials

■ Copper Alloy Bearing Bush Casting Method:

The copper sleeve with larger diameter and brighter lead is made of centrifugal casting; the copper sleeve with small diameter and less segregation of chemical composition adopts sand casting.