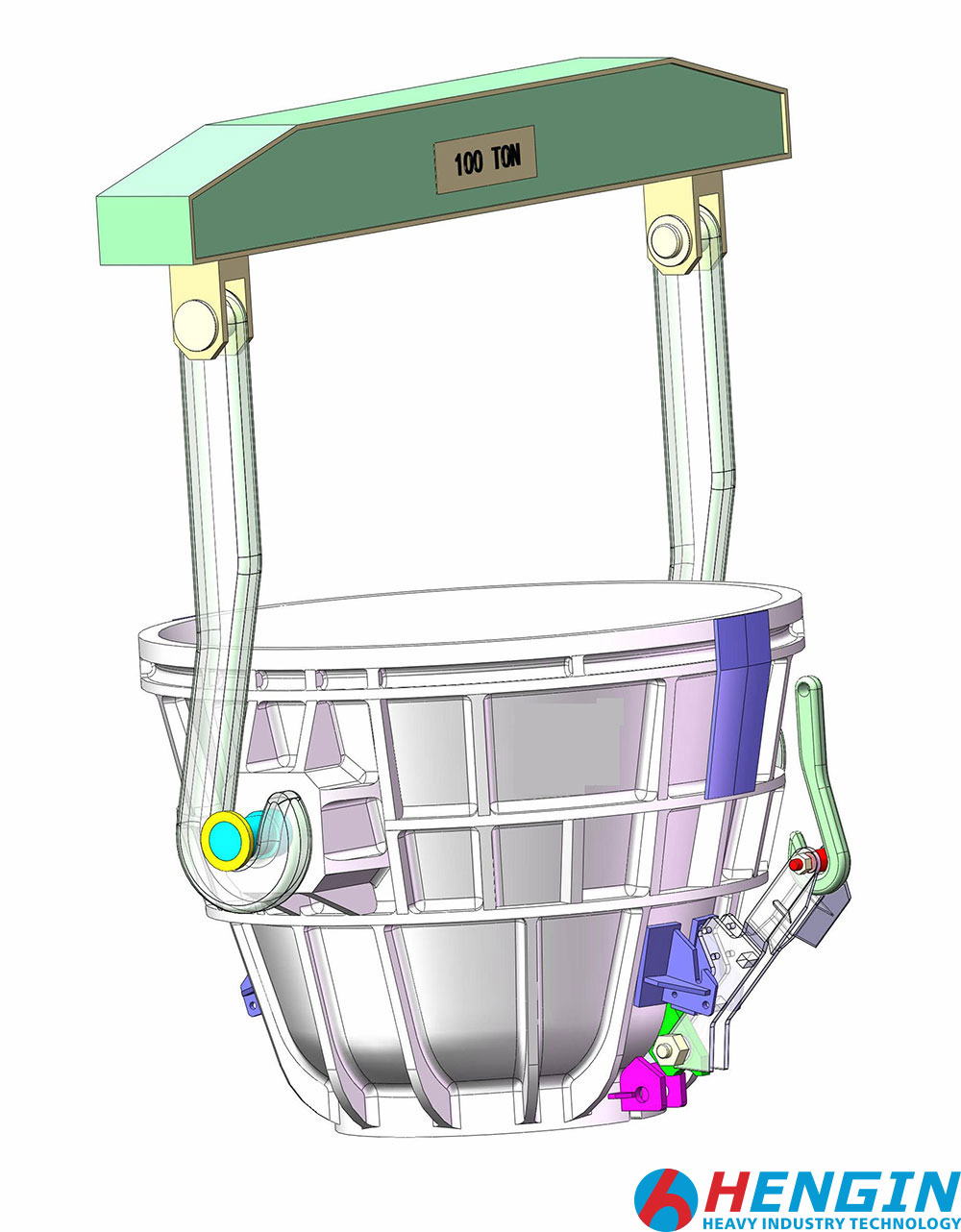

In January 2021, our company designed and manufactured two 100t EAF slag pots for Baosteel, with a unit weight of 28T and a designed service life of 24 months. It has been manufactured in recent days, and all technical indexes such as material composition, mechanical properties and NDT have reached the ideal state.This time, we are responsible for the structural design, process design and the whole process of product manufacturing of cast steel slag pot according to the user's requirements. So we use CAD / CAE to optimize the wall thickness structure of slag pot, the distribution of grid on the outer surface, and calculate the material mechanics to determine the stress state of lifting trunnion.

CAD / CAE Design Of Cast Steel Slag Pot - Fig.1

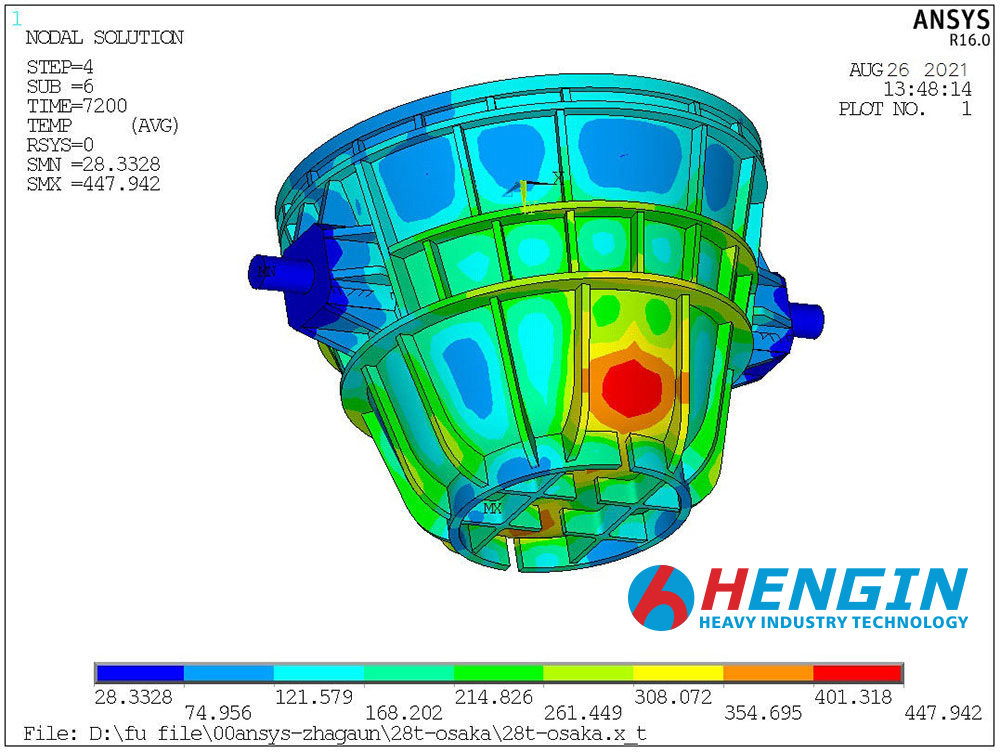

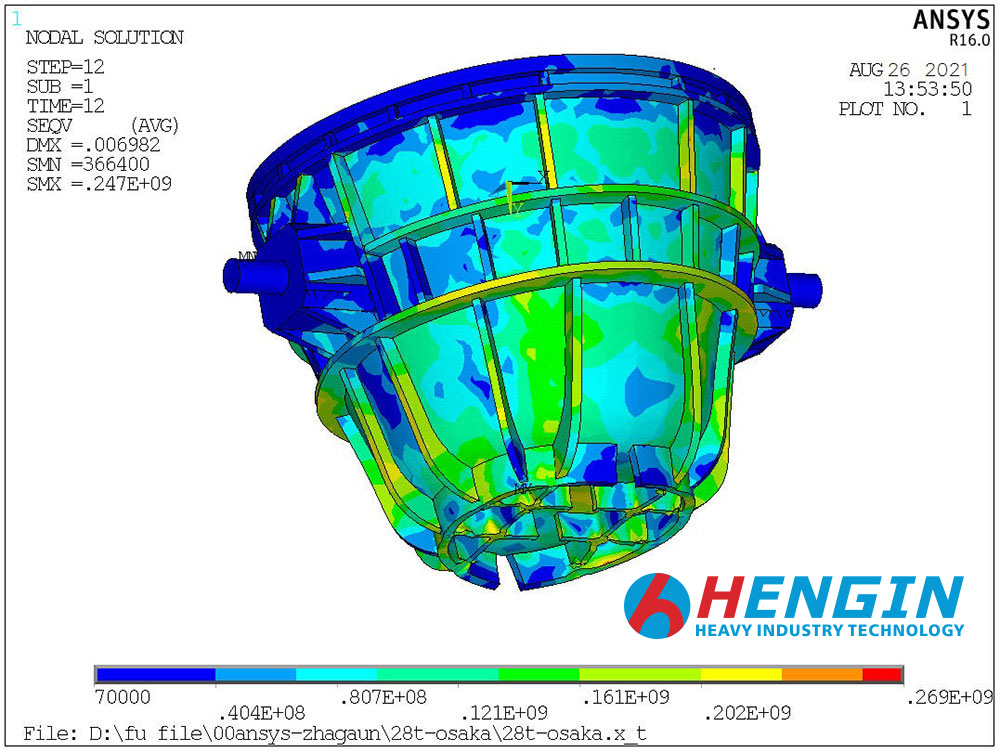

In the aspect of measuring the temperature field distribution, we use ANSYS software for simulation analysis to achieve uniform temperature distribution, avoid uneven cooling of slag pot, produce stress concentration and affect the service life of slag pot, and cooperate with the application of ProCAST software to confirm each other, further optimize the casting process design, and comprehensively improve the reliability and stability of cast steel slag pot product quality. Accumulated valuable data for the subsequent slag pot design and manufacturing, more accurately guided our work in slag pot products, serving customers.

ANSYS Analysis Of Temperature Field Of Cast Steel Slag Pot - Fig.2

ANSYS Analysis Of Temperature Field Of Cast Steel Slag Pot - Fig.3

28T Cast Steel Slag Pot - Fig.4

28T Cast Steel Slag Pot - Fig.5