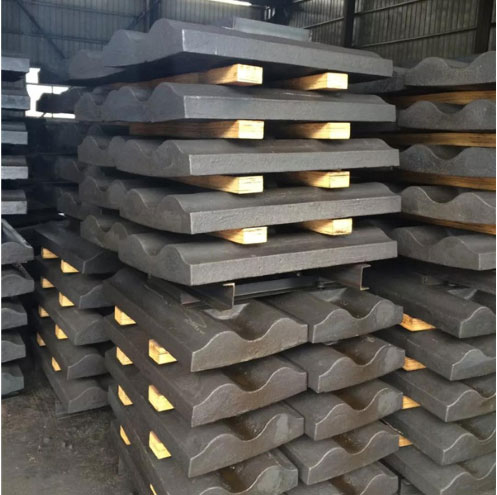

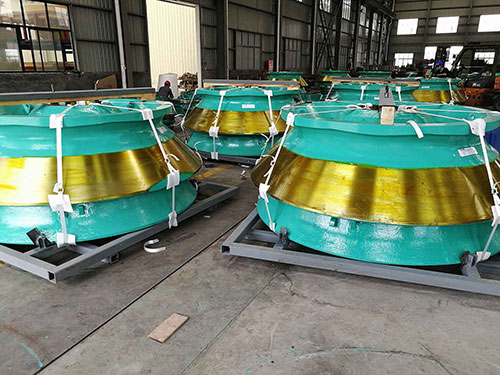

■ Working condition of crusher spindle

Large-scale hydraulic gyratory crusher is an important crushing equipment used in building materials, mines and cement industries. It is mainly used for crushing various ores or rocks. As one of the key components of crusher, the Main Shaft mainly bears the bending moment produced by the crushing force. Its manufacturing cycle and quality directly affect the manufacturing cycle and quality of the whole set of equipment. The impact force produced by hammer impact material is often uneven in the process of processing, installation and work, and micro-cracks are gradually formed in the stress concentration area and gradually expand, resulting in sudden brittle fracture. Over the years, the analysis of the fracture causes of the crusher Main Shaft is very complicated, such as the size design and structure of the Main Shaft, the selection of materials, cold and hot processing technology, loading status, installation quality and use, etc. Our company has optimized the design, casting, forging and heat treatment process of the main shaft of the hydraulic gyratory crusher, which can not only better control the flow direction of metal fibers in the deformation process of the main shaft of the crusher, make the flow direction of the taper section of the main shaft continuous, but also effectively shorten the processing cycle, improve production efficiency and ensure the processing quality of the main shaft quantity. The technical indicators of the products have reached the advanced level of similar products in the world. They have many advantages, such as high reliability, long service life, convenient operation and maintenance, safety, high automation, low installation and maintenance cost, and so on.

■ Technical Standards Large-scale hydraulic gyratory crusher is an important crushing equipment used in building materials, mines and cement industries. It is mainly used for crushing various ores or rocks. As one of the key components of crusher, the Main Shaft mainly bears the bending moment produced by the crushing force. Its manufacturing cycle and quality directly affect the manufacturing cycle and quality of the whole set of equipment. The impact force produced by hammer impact material is often uneven in the process of processing, installation and work, and micro-cracks are gradually formed in the stress concentration area and gradually expand, resulting in sudden brittle fracture. Over the years, the analysis of the fracture causes of the crusher Main Shaft is very complicated, such as the size design and structure of the Main Shaft, the selection of materials, cold and hot processing technology, loading status, installation quality and use, etc. Our company has optimized the design, casting, forging and heat treatment process of the main shaft of the hydraulic gyratory crusher, which can not only better control the flow direction of metal fibers in the deformation process of the main shaft of the crusher, make the flow direction of the taper section of the main shaft continuous, but also effectively shorten the processing cycle, improve production efficiency and ensure the processing quality of the main shaft quantity. The technical indicators of the products have reached the advanced level of similar products in the world. They have many advantages, such as high reliability, long service life, convenient operation and maintenance, safety, high automation, low installation and maintenance cost, and so on.

◆ Chemical Constituents

◆ The chemical composition standard ASTMA 668D is shown in Table 1

C |

Si |

Mn |

S |

P |

0.35~0.45 |

≤0.40 |

1.45 ~ 1.80 |

≤0.02 |

≤0.02 |

◆ Technical Requirements for Mechanical Properties

Tensile Strength / MPa |

Yield Strength / MPa |

Elongation( % ) |

Section Shrinkag( % ) |

Hardness( HB ) |

≥517 |

≥259 |

≥19 |

≥30 |

149 ~ 207 |