■ Introduction to Mining Grinding Mill Girth Gear

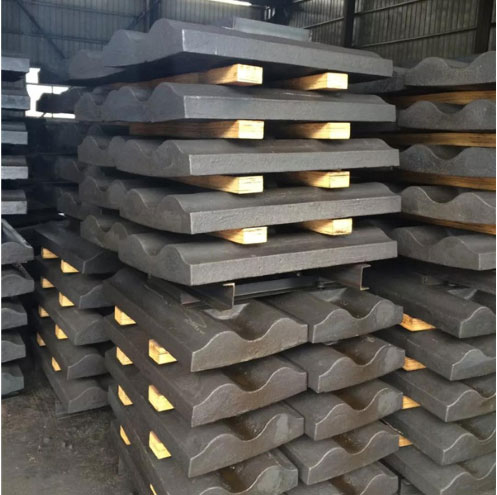

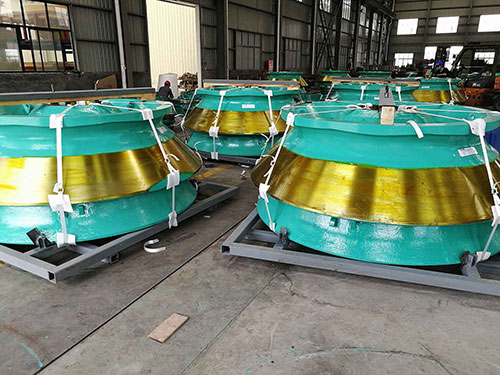

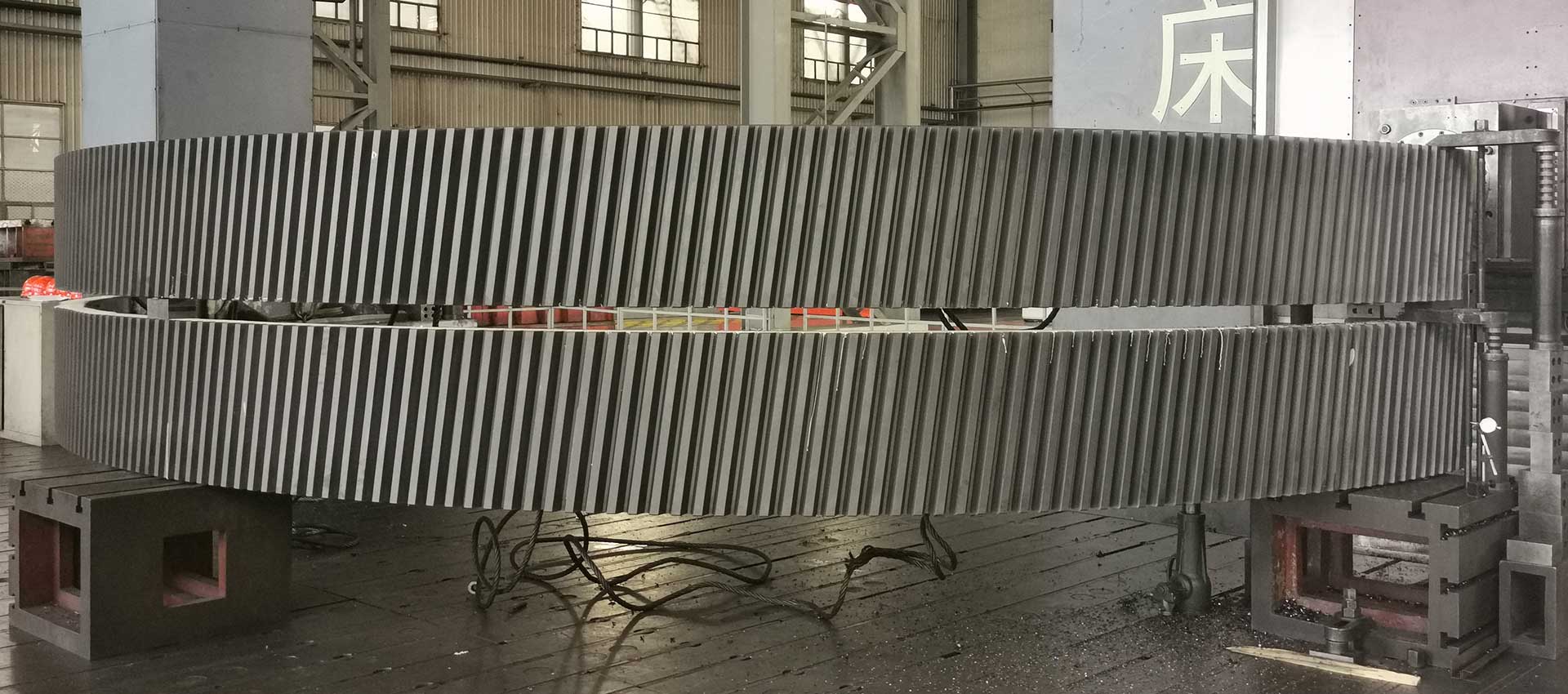

Girth Gear is the main part of Mining Grinding Mill's main transmission device, which drives the mill shell together with the pinion shaft. There are very high requirements for the design and manufacture of Grinding Mill Girth Gear in large mines. In order to ensure the smooth operation of the equipment, Girth Gear generally adopts the structure of open helical gear; the material is based on ASTM&ISO standards; the rough casting ensures that the microstructure is dense and there are no casting defects; the machining and hobbing ensure the accuracy of the tooth surface; the hardness of the Girth Gear after heat treatment Other mechanical properties meet the design requirements; NDT is strictly implemented in accordance with ASTM or GB design standards.Mining Mill Girth Gear from Hengin main features are large-modulus, large-diameter, high precision, high wear resistance, long life, integral or split casting products used in Ball mill, AG mill, SAG mill and Rod mill in the mining field.In addition.

■ Material Standards for Mining Grinding Mill Girth Gear

Complying with the American Society of Testing Material and the International Standardization Organization (ASTM&ISO) standards ANSI/AGMA 2015 and GB/ T10095-2008 or according to the requirement by the user.

■ Manufacturing Standard for Mining Grinding Mill Girth Gear

AGMA6114—2006 (Metric) Accuracy class, calculating according to Q8 accuracy class, processing according to Q10 precision class, or according to the requirement by the user's drawings.

■ Manufacturing Process

Casting→Annealing→Roughing→NDT→Gear Hobbing→Normalizing or Quenching and Tempering→NDT→Finishing→Packaging.

■ Main Parameters for Mining Grinding Mill Girth Gear

Girth Gear Standard |

Max Modulus |

Max Hardness |

Max Diameter/mm |

Accuracy |

Max Weight/Kg |

Structure |

Manufacturing Method |

| ANSI/AGMA 2015 , GB/T10095-2008 | 50 | HB350 | 14500 | Q10 | 144000 | Whole, valved | Casting, Machining |

■ Hengin's Mining Grinding Mill Girth Gear Experience

We can provide cost-effective Girth Gear products for CITIC, FLSimdth ball mills, SAG mill, AG mill.Based on the experience of casting, heat treatment, machining, girth gear manufacturing and equipment operation feedback, our company has three kinds of girth gear casting materials whose chromium, nickel and molybdenum components are different that meet the three different design strength and hardness requirements. Factors such as performance, modulus, pressure angle and helix angle, tooth width, tooth surface contact pressure, and axial force are considered to optimally design the grinding mill girth gear. For milling transmission, a 25° pressure angle is used to increase the milling capacity by approximately 10% compared to a 20° pressure angle. The helix angle is also limited to 7.5° to maintain the control of the axial force. Because the helical gear transmission is larger than the spur gear transmission which has the same diameter, the bending strength and contact strength are greatly improved, the transmission is stable, the noise is small and the service life is long.